TM 5-4240-501-14&P

STARTERS-Briggs & Stratton

Gear Drive 12V & 120V

CAUTION: DO NOT clamp motor housing in a vise or

strike with a steel hammer. Starter motors contain two

powerful magnets which can be broken or cracked if the

motor housing is deformed or dented.

Activate the starter motor and note readings of ammeter

and tachometer (RPM). Note length of starter motor

housing as shown on page 9 and refer to Fig. 91. A

starter

motor

in

good

condition

will

be

within

specifications listed.

Motor Housing

Minimum

Maximum

Length

Motor RPM

Amperes

3-1/16" (77.8 mm)

6500

18

3-3/4" (95.3 mm)

6900

19

Fig. 91 - 12 Volt DC Starter Motor Specifications

120 VOLT AC STARTER MOTOR

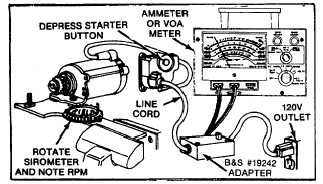

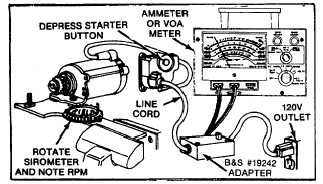

Connect the starter motor and ammeter as shown in Fig.

92.

DANGER: It is recommended that the starter motor be

Hi-Pot tested after final re-assembly.

CAUTION: The performance test of this starter requires

the use of an ammeter, connected in the 120 volt AC line

cord. Extreme care should be used in making this test to

minimize the hazard of electrical shock.

Fig. 92 - Checking Starter Motor Performance

Plug the electrical cord into a 120 volt outlet and press

the starter motor button. Note the readings of

tachometer or sirometer (RPM) and ammeter. A starter

motor in good condition will be within the following

specifications. Fig. 93.

Motor Housing

Minimum

Maximum

Length

RPM

Amperes

3-1/2" (88.9 mm)

6500

2.7

Fig. 93 - Starter Motor Specifications

If either the 120 VAC or 12 VDC starter motor does not

perform satisfactorily, the following should be checked

and corrected if necessary.

1.

A binding or seizing condition in the starter motor

bearings.

2.

Starter motor brushes sticking in brush holders.

3.

A dirty or worn armature commutator or brushes.

4.

A shorted, open or grounded armature.

A.

Shorted armature (wire insulation worn and

wires touching one another). Will be indicated

by low or no R.P.M.

B.

Open armature (wire broken) will be indicated

by low or no RPM.

C.

Grounded armature (wire insulation worn and

wire touching armature lamination or shaft).

Will be indicated by excessive current or no

RPM.

5.

A defective starter motor switch.

6.

A defective starter motor rectifier assembly. (120

volt AC only).

7.

Weakened magnets.

DISASSEMBLY OF STARTER MOTORS

Study Fig. 84 prior to starter motor disassembly.

Remove thru bolts. The drive head end may now be

removed. Inspect bushing for wear. If worn, replace

drive head end assembly. Fig. 94.

NOTE: MATCH MARKS AND THRU BOLTS MUST BE

PLACED

IN

THE

SAME

POSITION

AS

WHEN

RELMVOVED OR INTERFERENCE MAY RESULT.

(See checking starter motor drive if repair, cleaning or

replacement of drive assembly is necessary.)

Fig. 94 - Removing Thru Bolts

26