TM 9-2350-238-34-1

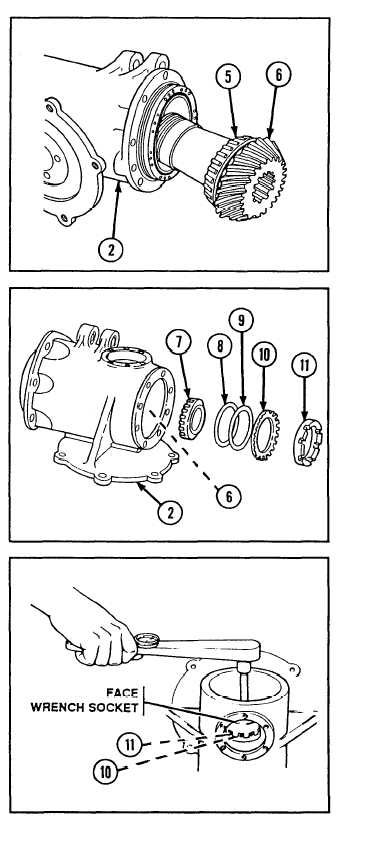

5

6

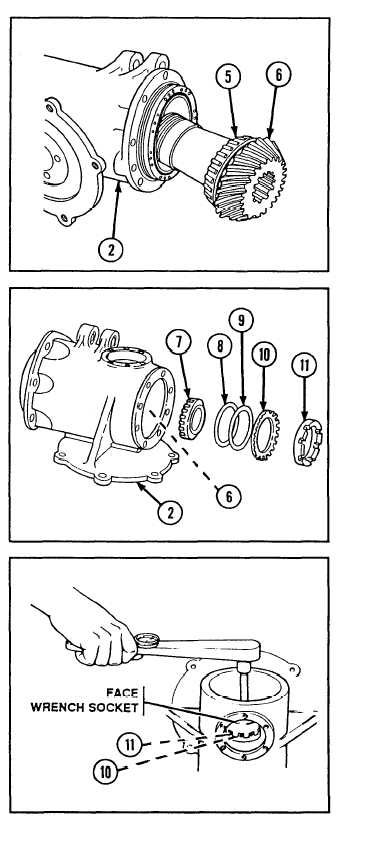

7

8

Install output drive spiral pinion gear (6)

and attached cone and rollers (5) into

g e n e r a t o r d r i v e m e c h a n i c a l h o u s i n g ( 2 ) .

E n s u r e g e a r s e a t s p r o p e r l y .

Coat tapered roller bearing (7) with

lubricating oil and install bearing cone over

end of output drive spiral pinion gear (6) in

g e n e r a t o r d r i v e m e c h a n i c a l h o u s i n g ( 2 ).

Ensure bearing is completely seated in

h o u s i n g.

Hold output drive spiral pinion gear (6) in

g e n e r a t o r d r i v e m e c h a n i c a l h o u s i n g ( 2)

and install key washer (8), flat washer (9),

key washer (10), and round plain nut (11)

on end of output drive spiral pinion gear.

U s i n g f a c e w r e n c h s o c k e t , t i g h t e n r o u n d

plain nut (11) until 15.0 to 25.0 in.-lb (1.7

to 2.8 N-m) is required to turn output drive

spiral pinion gear within its bearings. After

a d j u s t m e n t , b e n d t a n g s o f k e y w a s h e r ( 1 0)

into groove of round plain nut.

2 - 1 23