CHAPTER 8: MAINTENANCE OF SUSPENSION SYSTEM

TM 9-2350-256-20

8-10 REPLACE FINAL DRIVE SPROCKET AND HUB--Continued

WARNING

Sprocket is heavy. If sprocket is dropped, it may cause serious injury.

8

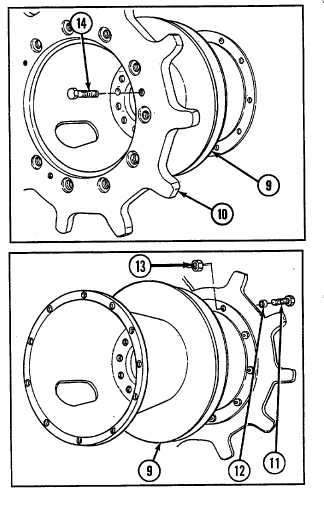

Remove inner sprocket (10) by installing three

jackscrews (14) in three holes provided. Tighten

jackscrews evenly and remove sprocket.

b. INSTALLATION

WARNING

Sprocket is heavy. If sprocket is

dropped, it may cause serious injury.

1

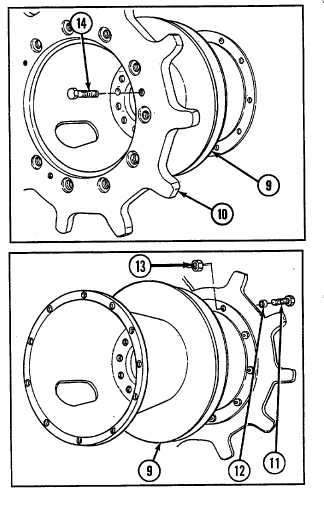

Install inner sprocket (10), 11 bushings (12), and 11

bolts (11) to track-drive hub (9). Torque bolts to

225-250 lb-ft (305-339 Nm).

2 Lubricate threads of 11 bolts (11) and 11 nuts (13)

with GAA grease and install nuts. Torque nuts to

70-90 lb-ft (95-122 Nm).

WARNING

All personnel are to stand clear of

vehicle hull when lifting. Sling failure

may cause severe injury or death.

3

Install lifting sling assembly and sling assembly on

track-drive hub (9).

4 Loosely install track-drive hub (9) and sprocket (10)

with dowel nut (8) to prevent track-drive hub from

falling. Remove lifting sling assembly and sling

assembly.

5 Lubricate mating surfaces of flange on final drive

and track-drive hub (9) with GAA grease.

6 Lubricate threads of 10 dowels (15) with GAA grease and install remaining dowel nuts (8). Torque dowel nuts to 450-

470 lb-ft (610-637 Nm). Wait 3 minutes and retighten dowel nuts. Wait 1 minute and check torque again.

7 Install outer sprocket (6), 11 bushings (4), and 11 bolts (3) to track-drive hub (9). Torque bolts to 225-250 lb-ft (305-

339 Nm).

8 Lubricate threads of 11 bolts (3) and 11 nuts (5) with GAA grease and install nuts. Torque nuts to 70-90 lb-ft (95-122

Nm).

9 Install hinged rear fender (2) with seven screws (1).

8-34