TM 9-2350-256-34-2

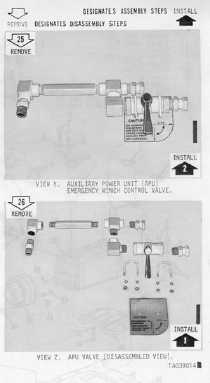

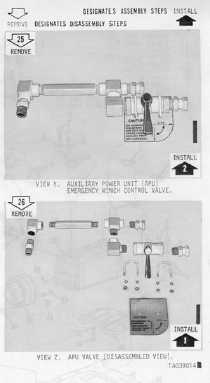

3-13. Repair of Hydraulic Subplate As-

sembly Components

a.

General. Remove and replace defective component

following sequence indicated in figure 3-20.

b.

Cleaning. Wash parts, except seals and gaskets, in

drycleaning solvent or mineral spirits paint thinner. Blow

parts with moisture-free compressed air; then immerse

parts in clean OE-10 oil, to prevent rusting.

c.

Inspection and Repair.

(1) Inspect all screws, plugs, nuts and fittings for

damaged threads and hex or socket heads for rounded

corners.

(2) Inspect all tapped holes for damaged

threads. Repair damaged threads with thread

chaser.

(3) Inspect valve bodies for cracks.

3-14. Assembly of Hydraulic Subplate

Assembly from Subassemblies

Assemble the hydraulic subplate assembly in reverse order

of disassembly (fig. 3-20)

Figure 3-20. Disassembly of hydraulic subplate assembly

into subassemblies (Sheet 5 of 5).

Section IV. REPAIR OF MECHANICAL TRANSMISSION AND MAIN HYDRAULIC PUMP

ASSEMBLY

3-15. Description

The mechanical transmission and main hydraulic pump assembly (figs. 1-10 and 1011) is mounted in the hull beneath

the crew compartment. A power takeoff from the main engine drives the transmission which is coupled to the hydraulic

pump. The power hydraulic takeoff is engaged or disengaged by an internal transmission clutch,

3-16.

Disassembly of Mechanical Transmission and Main Hydraulic Pump Assembly into Subassemblies

a. General. Figure 3-21, with its accompanying legend, serves to identify all subassemblies and attaching parts. The

legend also provides an index to the step-by-step removal of each particular subassembly.

b. Disassembly Procedure. Disassemble the mechanical transmission and main hydraulic pump assembly into

subassemblies as shown in figures 3-21 and 3-22

Change1

3-31