TM 9--2350--292--20--2

0449 00--1

DRIVER’S, PERSONNEL AND MECHANIC’S HATCH CUSHIONING PAD

REPLACEMENT

0449 00

THIS WORK PACKAGE COVERS:

Removal, Installation

INITIAL SETUP:

Tools

Electrical disk sander (item 69, WP 0717 00)

Abrasive wheel (item 70, WP 0717 00)

Welding shop trailer mounted (item 71, WP 0717 00)

Equipment Conditions

Doors opened for ventilation (TM 9--2350--292--10)

References

TM 9--2350--292--10

TC 9--237

Removal

WARNING

Unsafe welding practices can cause serious injury from

fire, explosions, or harmful agents. Allow only authorized

personnel to weld or cut metals. Follow safety precau-

tions in TC 9--237. Protective clothing and goggles must

be worn, adequate protective equipment used, a suitable

fire extinguisher kept nearby and requirements of TC

9--237 strictly followed.

NOTE

There are six hatch cushioning pads. All hatch cushion-

ing pads are replaced in the same manner. This task re-

places only one hatch cushioning pad.

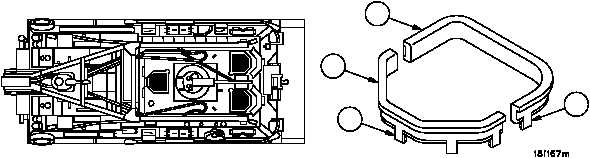

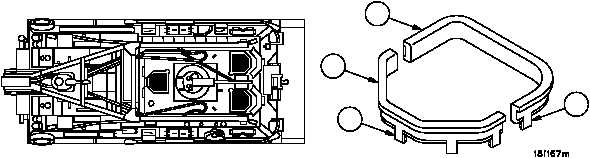

1. Cut tabs (1) on hatch cushioning pad (2), remove cushioning pad (2) from hull.

2. Grind welds and tabs (1) from hull to provide smooth surface and paint free metal for installation of new cushion-

ing pad (2) in accordance with TC 9--237.

Figure 228

2

2

1

1