TM 9-2350-238-10

TRACK–CONTINUED

DECREASING TRACK TENSION

1 Drive vehicle onto hard level ground.

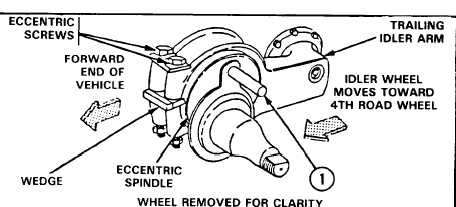

2 Drive vehicle slowly in reverse until hole

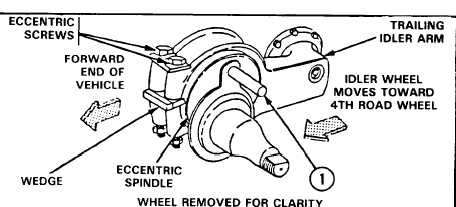

Bar must not travel below

through hub flange of trailing idler wheel

centerline of trailing idler arm.

is alined with hole in eccentric shaft

Ensure spindle arm clearance is

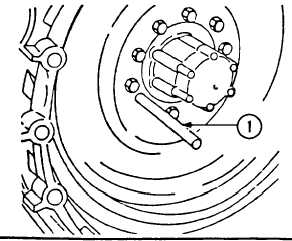

spindle. Insert 10 in. (25.4 cm) of bar

(1) (item 5, appx B) through hub flange

correct. Refer to page 3-48.

3

and into spindle.

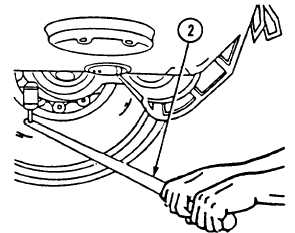

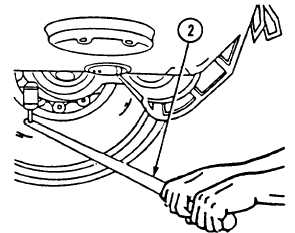

Loosen self-locking nuts on eccentric

spindle screw, using socket wrench (2)

(item 83, appx B). Nuts are torqued to

600 ± 25 ft-lb (810 ± 34 N-m) (oiled

threads and washer). Drive wedge (item

72, appx B) into joint to relieve tension

on eccentric spindle.

4 Move vehicle slowly rearward, rotating

bar and eccentric spindle 1/4 to 1/2 turn,

and decrease track tension.

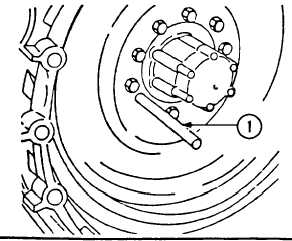

5 Remove wedge from spindle. Tighten ec-

centric spindle screws and nuts as tight

as possible using socket wrench. As

soon as possible have unit maintenance

personnel check and torque spindle nuts

to 600 ± 25 ft-lb (810 ± 34 N-m) (oil-

ed threads and washer).

3-46