TM 9-2350-238-10

TRACK–CONTINUED

TRACK REMOVAL AND INSTALLATION–CONTINUED

4

5

6

7

8

9

10

11

Be sure fixtures are seated pro-

perly, Injury to personnel may

result if they fall off.

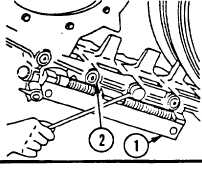

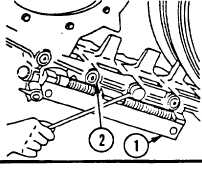

Install two track connecting fixtures (1)

across track shoe to be removed.

Tighten fixtures equally to relieve tension

on track pins.

Remove self-locking nut (2) from track

pin.

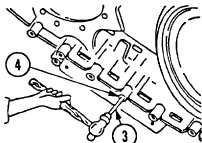

Do not damage track pin

threads during removal,

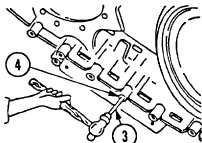

Using short leg of drift pin (3) start to

drive track pin (4) out of track shoe (5).

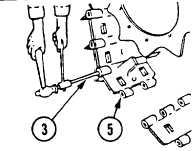

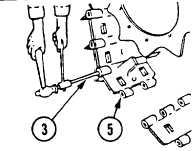

Remove track pin (4) with long leg of

drift pin (3).

Remove track shoe (5) connecting fixture

(l) .

Repeat steps 5 and 6 for remaining track

pin (4) and remove track shoe (5).

Partially install one self-locking nut (2) on

each track pin (4).

Position track shoe (5) being installed at

one end of disconnected track. Lift shoe

approximately 15 degrees to aline hex-

agon shape of bushing and insert track

pin (4). Drive track pin through shoes by

tapping lightly with hammer on end of

nut. Install remaining self-locking nut (2)

on opposite end of track pin (4).

Install two track connecting fixtures (1)

across track shoes to be connected and

tighten equally until holes in ends of

track are aligned, Connect shoes with

track shoe track pin (4) as in step 10

and install remaining self-locking nut (2).

12 Tighten all nuts as much as possible.

Remove track connecting fixture. As

soon as possible, have unit maintenance

personnel torque nuts to 160-200 ft-lb

(216-270 N-m).

NOTE

A minimum of 1/8 track pin

thread must extend through

both track pin nuts.

13 Adjust track tension. Refer to page 3-45.

3-49