GENERAL INFORMATION

CORRECT LUBRICATION IS IMPORTANT

Any high quality detergent oil having the American Petroleum Institute classification “For Service SC, SD, SE or MS” can

be used in Briggs & Stratton engines. Detergent oils keep the engine cleaner and retard the formation of gum and varnish

deposits.

SUMMER

WINTER

(Above 40° F.)

(Under 40° F.)

Use SAE 30

Use SAE 5W-20 or SAE 5W-30

If not available,

If not available,

Use SAE 10W or SAE 10W-30

Use SAE 10W-30

Below 0° F,

or

Use SAE 10W or SAE 10W-30

SAE 10W-40

Diluted 10% with Kerosene

The oil recommendations are the result of extensive testing. No special additives should be used.

OIL SHOULD BE CHANGED AFTER EACH 25 HOURS OF ENGINE OPERATION. (More often under dirty operating

conditions). In normal running of any engine, small particles of metal from the cylinder walls, pistons and bearings will

gradually work into the oil. Dust particles from the air also get into the oil. If the oil is not changed regularly, these foreign

particles cause increased friction and a grinding action which shorten the life of the engine. Fresh oil also assists in

cooling, for old oil gradually becomes thick and loses its cooling effect as well as its lubricating qualities.

The air cleaner should be serviced every 25 hours of engine operation. Dirty operating conditions re-quire more frequent

servicing.

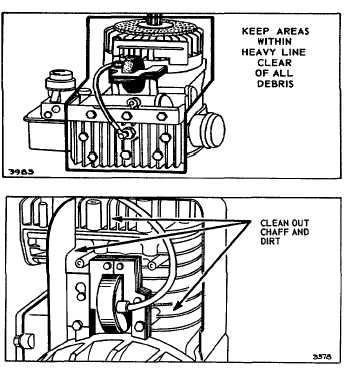

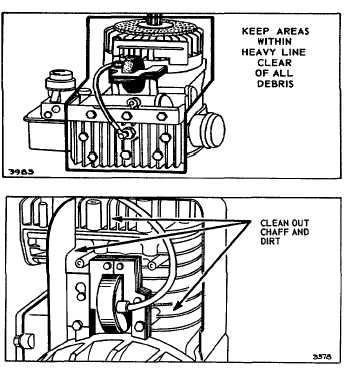

CLEAN COOLING SYSTEM

Grass particles, chaff or dirt may clog the air cooling system, expecially after prolonged service in cutting dry grasses.

Continued operation with a clogged cooling system may cause severe overheating and possible engine damage. The

figures below show the blower housing removed and area to be cleaned. This should be a regular maintenance

Operation.

1