TM 5-4240-501-14P

IGNITION

General

Repair Instructions IV (Form 4750)

Section 2

IGNITION

Three basic types of ignition systems are used

1.

MAGNETRONTM ignition, a self-contained

transistor module (no moving parts) and ignition

armature.

2.

A flywheel type, having either an internal or

external breaker system. Fig. 4 and Fig. 25.

3.

The Magna-Matic system, having the armature

and rotor behind the flywheel, and an external

breaker system. Fig. 44.

Check Ignition

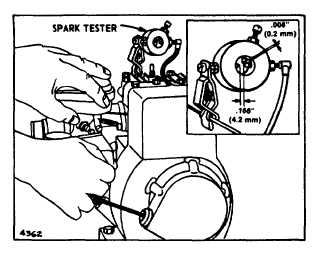

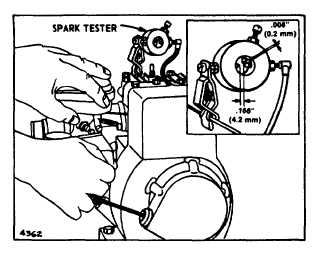

Remove the spark plug. Spin the flywheel rapidly with

one end of the ignition cable clipped to the 19051 tester

and with the other end of the tester grounded on the

cylinder head. If spark jumps the .166" (4.2 mm) tester

gap, you may assume the ignition system is functioning

satisfactorily.

Fig. 1.

NOTE:: Flywheel must rotate at 350 RPM, minimum with

MAGNETRON’" ignition.

Fig. 1 - Checking Spark

NOTE: If engine runs but misses during operation, a

quick check to determine if ignition is or is not at fault

can be made by inserting the 19051 tester between the

ignition cable and the spark plug. A spark miss will be

readily apparent.

While conducting this test on Magna-Matic equipped

engines. Models 9, 14, 19 and 23, set the tester gap at

.060" (1.5 mm).

SPARK PLUG

The plugs recommended for Briggs & Stratton engines

are as follows:

1-1/2"

2"

Manufacturer’s

Plug

Plug

Part Number

CJ-8

J-8

Champion

RCJ-8

RJ-8

Champion Resistor

235

295

Autolite

245

306

Autolite Resistor

WS9E

-

Robert Bosch

3/4"

13/16"

Plug wrench (deep socket)

NOVEMBER. 1983

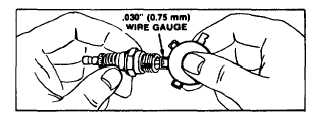

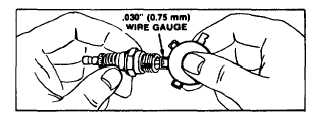

Clean spark plug with a pen knife or wire brush and

solvent and set gap at .030" (0.75 mm) for all models. If

electrodes are burned away, or the porcelain is cracked,

replace with a new plug. DO NOT USE ABRASIVE

CLEANING MACHINES.

Fig. 2.

Fig. 2 - Adjusting Spark Plug Gap

Coil and Condenser Testing . All Models

Use an approved tester to test coils and condensers.

Specifications are supplied by the tester manufacturer or

refer to MS-7862, Testing Briggs & Stratton Ignition

Coils.

NOVEMBER, 1983

2

1