TM 5-4240-501-14P

IGNITION

MAGNETRONTM

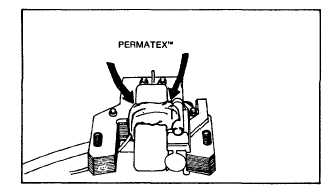

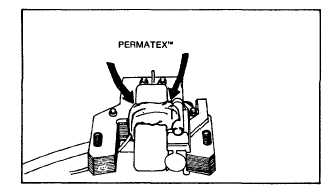

INSTALLING MAGNETRONT" MODULE

Module is installed in reverse order of removal. Note

that module retainer must be on back side of coil

laminations, Fig. 8. Use Permatex’" or similar sealant to

hold ground wires in place, Fig. 8

Ignition timing is controlled by the location of the flywheel

and crankshaft keyways on aluminum engines. On cast

iron engines, refer to page 9.

Fig. 8 -

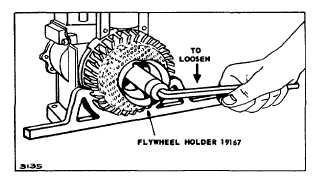

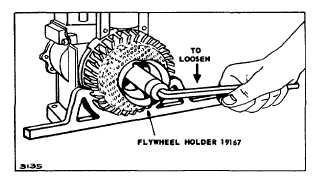

Starter Clutch On flywheels of 6-3/4" (171 mm) diameter

or less, use flywheel holder 19167, to keep flywheel from

turning. On rope starter engines, the 1/2" diameter

thread flywheel nut is left handed and the 5/8" diameter

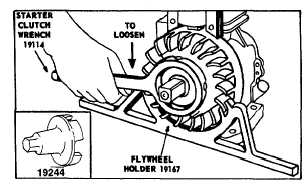

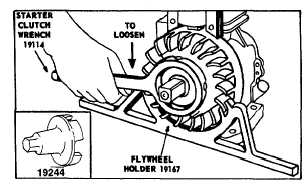

thread is right handed. Fig. 9. Starter clutch used on

rewind and wind-up starter has a right hand thread. Fig.

10. Remove clutch using P/N 19114 starter clutch

wrench or P/N 19244 or 19161 1/2" square drive starter

clutch wrench.

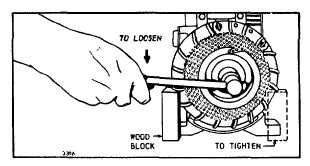

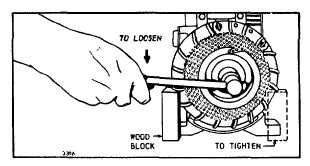

For flywheels or larger diameter place a block of wood

under flywheel fin to prevent flywheel turning while

loosening nut or starter clutch. Clamp engine base

securely. Fig. 11.

Fig. 9 Loosen Flywheel, Rope Starter (1/2" Dia.

Threads)

Figure. 10 - Loosening Flywheel

Rewind Starter and Wind-up Starter Engines

Fig. 11 - Loosening Large Flywheels

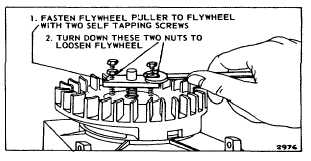

Remove Flywheel

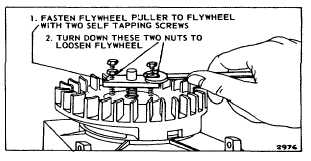

Some flywheels have two holes provided for use of a

flywheel puller. Use puller shown in Table 1. Leave nut

loose on threads of crankshaft for puller to bear against,

Fig. 12. Small cast iron flywheels do not require a

flywheel puller. See note below.

Fig. 12 - Removing Flywheel

NOTE : To remove small cast iron flywheels without

puller holes. support the flywheel with a gloved hand.

exerting an upward pull. Using a rawhide hammer.

strike the outside rim of the flywheel with a sharp blow.

Several blows may be required on an extremely tight

flywheel.

NOTE Care is required not to damage the flywheel fins.

magnets or ring gear

2

2

4