TM 5-4240-501-14P

IGNITION

Flywheel Type - MAGNETRONTM - External Breaker

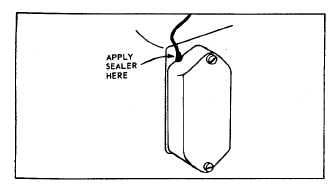

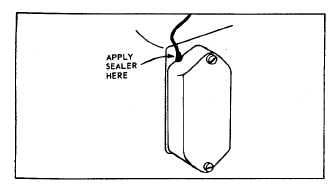

Fig. 28 - Sealing Breaker Cover

TIMING MAGNETRONTM IGNITION

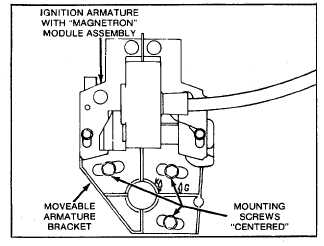

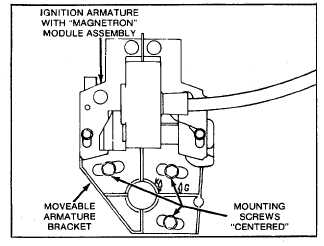

1

Gasoline

-

Position

armature

bracket

so

mounting screws are centered in armature

bracket and tighten screws, Fig. 29A.

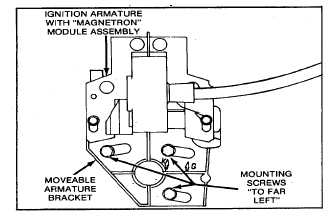

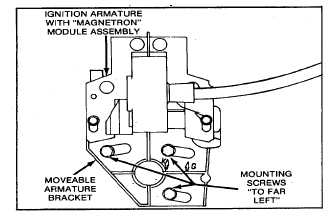

2.

Kerosene - Position armature bracket to the

right, as far as it will go and tighten screws, Fig.

29B.

Fig. 29A- Gasoline Operation

Fig. 29B- Kerosene Operation

ADJUST ARMATURE TIMING WITH

BREAKER POINTS

MODEL SERIES 193000, 200000, 230000 ,

243000, 300000, 320000

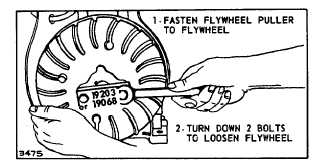

Remove Flywheel

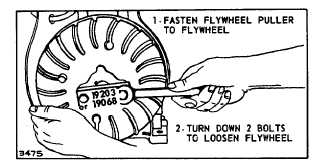

Use puller 19203 or 19068, running puller screws into

holes tapped into flywheel. Continue to tighten screws

until flywheel loosens, Fig. 30. NOTE: Use flywheel nut

to protect crankshaft threads.

Fig. 30 - Removing Flywheel

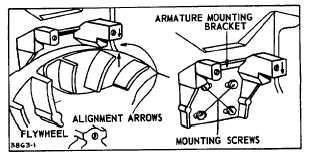

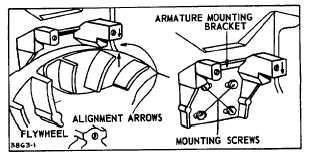

Set point gap at .020" (0.5 mm). Position flywheel on

crankshaft taper. Slip key in place. Install flywheel nut

finger tight. Rotate flywheel and crankshaft clockwise

until breaker points are just opening. Use a timing light.

When points just start to open, arrow on flywheel should

line up with arrow on armature bracket, Fig. 31.

If arrows do not match, slip off flywheel without disturbing

crankshaft position. Slightly loosen mounting screws

holding armature bracket to cylinder, Fig. 31. Slip

flywheel back on crankshaft. Insert flywheel key. Install

flywheel nut finger tight. Move armature and bracket

assembly to align arrows. Slip off flywheel, tighten

armature bracket bolts. Install key and flywheel. Tighten

flywheel nut to torque specifications listed in Table No.

1. Set armature air gap at .010"-.014" (0.25-0.36 mm),

Fig. 32.

Fig. 31 - Timing Marks

2

9