TM 5-4240-501-14P

IGNITION

Magna-Matic

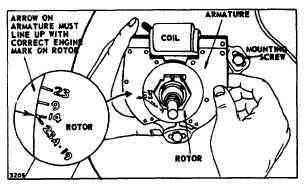

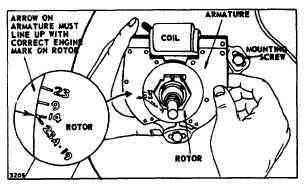

Fig. 50 - Adjusting Rotor Timing

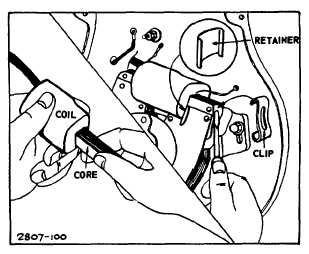

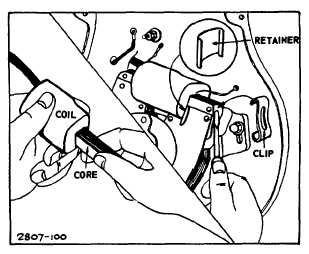

Replace Coil or Armature or Both

Usually the coil and armature are not separated, but are

left assembled for convenience. However, if one or both

need replacement, proceed as follows: The coil primary

wire and the coil ground wire must be unfastened. Pry

out the clips that hold the coil and coil core to the

armature. See Fig. 51. The coil core is a slip fit in the

coil and can be pushed out of the coil.

Fig. 51 - Replace Coil

To reassemble, push coil core into coil with rounded side

toward the ignition cable. Place coil and core on

armature with coil retainer between the coil and

armature, with rounded side toward the coil. Hook the

lower end of the clips into the armature; then press the

upper end onto the coil core, Fig. 51.

Fasten the coil ground wire (bare double wires) to the

armature support. (Replacing coil, Fig. 51). Now place

the assembly against the cylinder around the rotor and

bearing support. Insert the three mounting screws

together with washer and lockwasher into the three long

oval holes in the armature. Tighten them enough to hold

the armature in place but loose enough that the armature

can be moved for adjustment of rotor timing. See Fig.

50. Attach primary wires from coil and breaker points to

the terminal at the upper side of back plate. (This

terminal is insulated from back plate.) Push the ignition

cable through the louvered hole at left side of back plate.

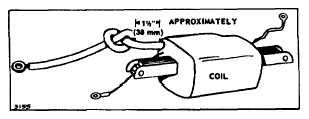

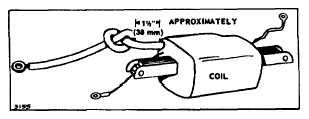

Fig. 52 - Shorten Cable - Model 9

NOTE: On Model 9 engines, knot the ignition cable

before inserting it through the back plate. See Fig. 52.

Be sure all wires clear flywheel.

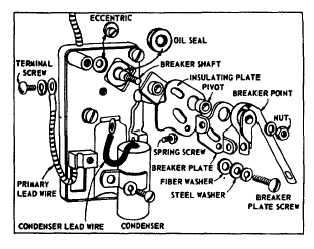

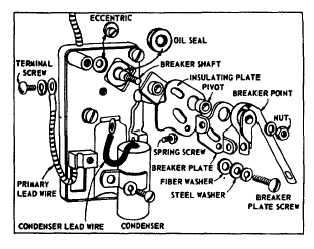

Remove Breaker Points

Turn crankshaft until points open to widest gap. This

makes it easier to assemble and adjust points later if

crankshaft is not removed. With terminal screw

removed, remove the spring screw. See Fig. 53.

Loosen the breaker shaft nut until nut is flush with end of

shaft. Tap nut to free breaker arm from tapered end of

breaker shaft. Remove nut, lockwasher and breaker

arm. Remove breaker plate screw, breaker plate, pivot,

insulating plate and eccentric. Pry out breaker shaft oil

seal with a sharp pointed tool.

Fig. 53 - Breaker Box Assembly

2

14