TM 5-4240-501-14P

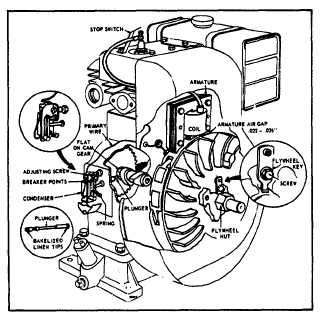

IGNITION

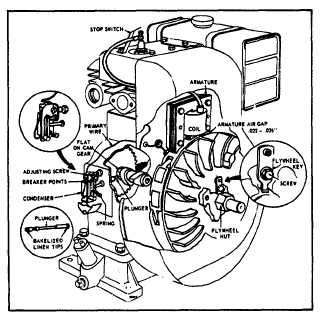

Flywheel Type - External Breaker

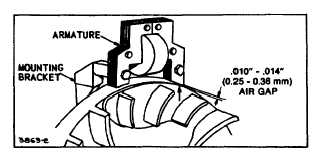

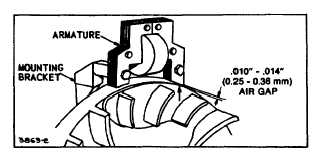

Fig. 32 - Armature Air Gap

ADJUST ARMATURE TIMING

Model Series 19D, 23D

Fig. 33 - Model Series 19D, 23D

Remove Flywheel

Use puller 19203 or 19068, running puller screws into

holes tapped into flywheel. Continue to tighten screws

until flywheel loosens, Fig. 30.

NOTE : Use flywheel nut to protect crankshaft threads.

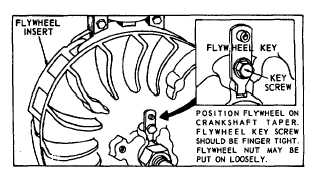

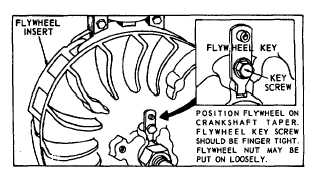

Set points at .020" (0.51 mm) gap. Position flywheel on

crankshaft taper. Flywheel key screw should be finger

tight. Flywheel nut may be put on loosely, Fig. 33.

Fig. 34 - Flywheel Key

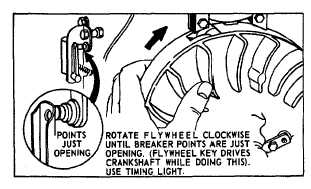

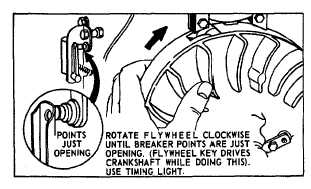

Rotate flywheel clockwise until breaker points are just

opening (flywheel key drives crankshaft while doing this).

Fig. 35. Use a timing light.

Fig. 35 - Flywheel Timing

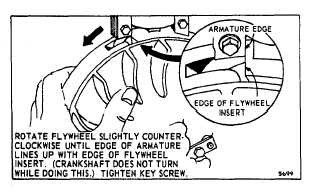

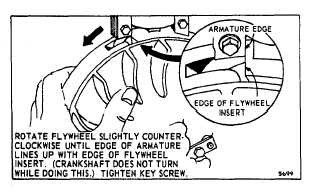

Rotate flywheel slightly, counterclockwise, until edge of

armature lines up with edge of flywheel insert, Fig. 36.

(Crankshaft must not turn while doing this.) Tighten key

screw. Tighten flywheel nut. See Table 1. Set armature

air gap at .022"-.026" (0.56-0.66 mm).

Fig. 36 - Flywheel Timing

2

10