TM 5-4240-501-14P

IGNITION

FLYWHEEL TYPE-- EXTERNAL BREAKER

MODEL SERIES 193000, 200000, 230000,

243000, 300000, 320000, 19D, 23D

Fig. 25 - Flywheel Ignition External Breaker

Models 193000, 200000, 233000, 243000,

300000, 320000

Replace Breaker Points -

Model Series 193000, 200000, 230000, 243000,

300000, 320000, 19D, 23D

Turn crankshaft until points open to widest gap. This

makes it easier to assemble and adjust points later if

crankshaft is not removed. Remove condenser and

upper and lower mounting screws. Loosen lock nut and

back off breaker point screw. Fig. 26. Reverse process

to install.

Fig. 26 - Breaker Points

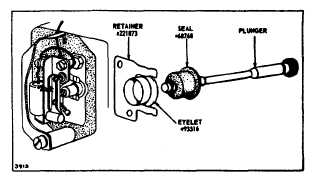

To avoid the possibility of oil leaking past the breaker

point plunger or moisture entering the crankcase

between plunger and bushing, a plunger seal is now

installed on engine models using this ignition system.

Fig. 27. These parts may be added to engines in the

field if contaminated points are experienced.

Fig. 27 - Seal Assembly

EXTREME

CARE

SHOULD

BE

TAKEN

WHEN

INSTALLING SEAL ON PLUNGER, OR SEAL MAY BE

FRACTURED.

NOTE:

Before

mounting

the

breaker-condenser

assembly, apply a sealer such as Permatex" to the

threads of both mounting screws and the adjustment

screw. The sealer prevents oil from leaking into the

breaker point area.

Mount

the

breaker

point

assembly,

then

tighten

adjustment screw until the locknut has pushed the ferrule

as far as possible toward the head of the adjustment

screw. This secures the adjustment screw firmly to the

breaker point.

Adjust and Clean Breaker Points

Turn the crankshaft until the points open to their widest

gap. Turn breaker point adjusting screw points open to

.020" (0.5 mm). Tighten locknut, while holding

adjustment screw, Fig. 26. To clean points turn

crankshaft until points are closed. Insert a piece of

lintless paper and draw the paper between the points.

Open the breaker points to withdraw the paper (so the

paper will not tear and allow a small portion to remain

between the points).

Apply additional sealer at the point at which the primary

wire passes under the breaker cover. This area must be

re-sealed to prevent the entry of dust and moisture. See

Fig. 28.

2

8