TM 5-4240-501-148P

CARBURETION

Air Cleaners

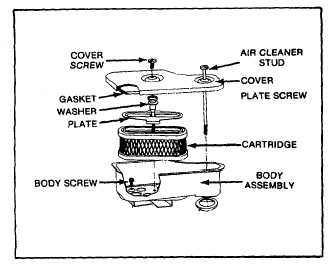

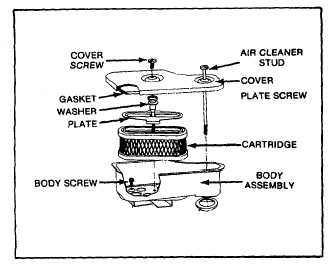

CARTRIDGE AIR CLEANER - REVERSE AIR FLOW

1.

Remove air cleaner stud, screw and gasket.

Replace gasket if damaged.

2.

Remove plate screw, washer and plate.

3.

Remove cartridge and clean air cleaner body

carefully to prevent dirt from entering carburetor

Brush dirt from body through holes into duct.

4.

Clean cartridge by tapping gently on flat surface.

a.

If very dirty, replace cartridge or wash in a low or

non-sudsing detergent and warm water solution.

b.

Rinse thoroughly from OUTSIDE IN until water is

clear.

c.

Cartridge must be allowed to stand and air dry

thoroughly before using.

5. Re-assemble air cleaner. Fig. 6.

Fig. 6 - Cartridge Air Cleaner

CAUTION: Petroleum solvents, such as kerosene, are

not to be used to clean cartridge. They may cause

deterioration

of

the

cartridge.

DO

NOT

OIL

CARTRIDGE. DO NOT USE PRESSURIZED AIR TO

CLEAN OR DRY CARTRIDGE.

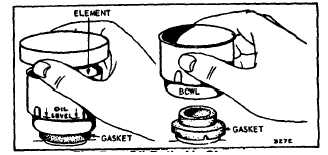

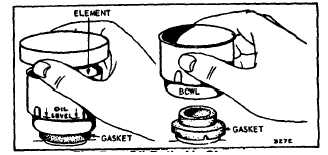

SERVICE OIL BATH AIR CLEANER

Pour out old oil from bowl. Wash element thoroughly in

solvent and drain dry. Clean bowl and refill with same

type of oil used in crankcase. See Fig. 7.

Fig. 7 - Oil Bath Air cleaner

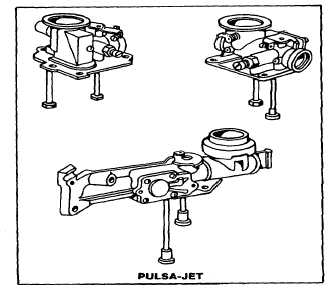

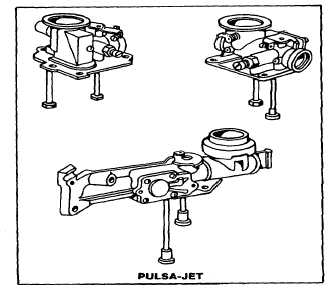

THREE BASIC CARBURETOR STYLES

There are three styles of carburetors used on Briggs &

Stratton engines. Page 3 and i, Fig. 8. Compare the

carburetor to be repaired with the illustrations to

determine style of carburetor and refer to that section for

repair information.

Before removing any carburetor for repair, look for signs

of air leakage, or mounting gaskets that are loose, have

deteriorated, or are otherwise damaged.

Note position of governor springs, governor link, remote

control or other attachments to facilitate re-assembly.

Do not bend the links or stretch the spring. (Section 4

illustrates popular engine models.)

Fig. 8 - Style of Carburetors

3