TM 5-4240-501-148P

CARBURETION

Automatic Choke

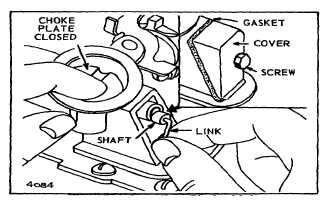

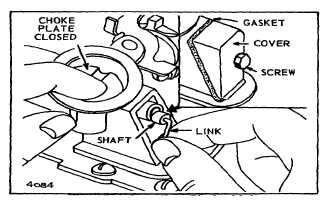

Fig. 15 -- Inserting Choke Link

Move choke plate to an over center position as shown in

Fig. 16. Tighten carburetor mounting screws in a

staggered sequence. Please note Opening the choke to

an over center position places the diaphragm in a

preloaded condition.

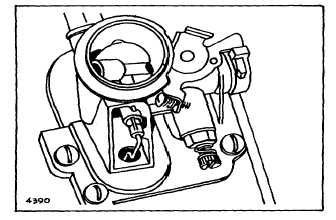

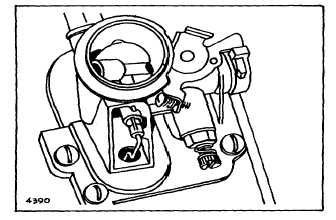

Move choke plate to a normal position. Choke plate

should now fully close, Fig. 16.

If choke valve is not fully closed, check to be sure choke

spring is properly assembled to diaphragm, and also

properly inserted in its pocket in the tank top. Install

choke link cover and gasket.

Fig. 16 - Pre-Loading Diaphragm

All carburetor adjustment should be made with the air

cleaner on engine. Best adjustment is made with a fuel

tank half full of gasoline.

To Adjust Carburetor:

1.

Start engine and run long enough to warm it to

operating temperature.

NOTE: If engine is out of adjustment so

that it will not start, close the needle

valve by turning it clockwise. Then open

needle

valve

1-1/2

turns

counterclockwise. Fig. 17.

Fig. 17 - Adjusting Carburetor

2. Move speed control lever to run engine at normal

operating speed.

a.

Turn needle valve in clockwise until engine starts

to lose speed (lean mixture).

b.

Then

slowly

turn

needle

valve

out

counterclockwise past the point of smoothest

operation until engine just begins to run unevenly

(rich mixture).

c.

Turn

needle

back

clockwise

to

midpoint

(smoothest operation) between rich and lean

mixture.

d.

Final adjustment of the needle valve should be

at the midpoint between rich and lean.

3.

Move engine to SLOW. Turn idle adjusting screw

until a fast idle is obtained 1750 R.P.M.

If the engine idles at a speed lower than 1750

R.P.M., it may not accelerate properly. It is not

practical to attempt to obtain acceleration from

speeds below 1750 R.P.M., since the richer mixture

which would be required, would be too rich for

normal operating speeds.

7