TM 5-4240-501-148P

CARBURETION

Pulsa-Jet, Vacu-Jet (Vertical Crankshaft)

4.

To check adjustment move engine control from

SLOW to FAST speed. Engine should accelerate

smoothly. If engine tends to stall or die out, increase

idle speed or re-adjust carburetor, usually to a

slightly richer mixture.

NOTE: Flooding can occur if the engine is tipped at

an angle for a prolonged period of time, if the engine

is cranked repeatedly when the spark plug wire is

disconnected or if carburetor mixture is adjusted too

rich.

In case of flooding, move the governor control to the

"Stop" position and pull the starter rope at least six

times. (Crank electric starter models for at least 5

seconds.)

When the control is placed in the "Stop" position the

governor spring holds the throttle in a closed (idle)

position. Cranking the engine with a closed throttle

creates a higher vacuum which opens the choke

rapidly, permitting the engine to clear itself of excess

fuel.

Then move the control to "Fast" position and start

engine. If engine continues to flood, lean carburetor

needle valve -1/8 to 1/4 turn clockwise or see page

5.

If the engine on a mower with a high-inertia disc type

cutter blade becomes hard starting when the engine is

warm, a leaner carburetor mixture may be required.

A heavy, high-inertia disc type cutter blade rotates for a

longer period of time, after the governor control is placed

in the STOP position. During this "coasting" period, the

engine continues to induct the fuel-air mixture, even

when the choke is open. If the carburetor mixture is too

rich, the warm engine may flood and become hard

starting. If the original carburetor adjustment has not

been changed, turn the needle valve clockwise (leaner)

approximately 1/8 turn. If the original carburetor

adjustment

has

been

changed,

follow

previous

adjustment procedure paragraph No. 2 A, B and C, then

adjust 1/8 turn leaner.

Cleaning Fuel System

Gummy or dirty fuel tanks, lines and carburetors should

be cleaned in a carburetor cleaner, such as Bendix. Do

not soak diaphragms or nylon parts in cleaner.

MODEL SERIES 82000, 92000, 94000, 110900 and

111900 only

Model Series 82500, 92500 and 94500 have a VacuJet

carburetor. Model Series 82900, 92900, 94900, 110900

and 111900 have a Pulsa-Jet carburetor.

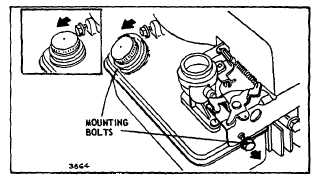

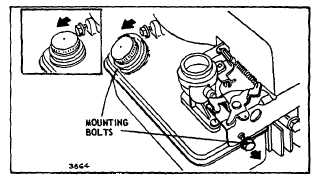

Remove carburetor and fuel tank assembly mounting

bolts, Fig. 18.

Fig. 18 - Removing Mounting Bolts

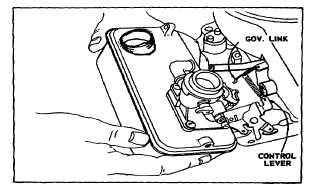

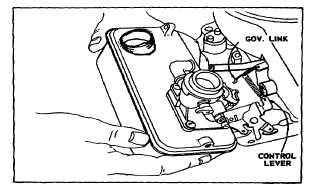

Slip carburetor and fuel tank assembly off end of fuel

intake tube and turn assembly to free throttle link from

throttle lever. This will leave governor link and governor

spring connected to the governor blade and control lever,

Fig. 19.

Fig. 19 - Remove Carburetor and Tank Assembly

MODEL SERIES 94000

Disconnect governor spring from control lever. Slide

carburetor and fuel tank assembly off end of fuel intake

tube and turn assembly to disconnect governor link from

bell crank lever. This will leave governor spring and bell

crank assembly on carburetor and fuel tank assembly,

Fig. 20.

8