TM 5-4240-501-148P

CARBURETION

Vacu-Jet, Pulsa-Jet

Model Series 82500, 92500 and 94500 engines should

be adjusted with fuel tank half full of gasoline.

Initial Adjustment: Turn needle valve clockwise to close

it. Then open 11/2 turns. This initial adjustment will

permit the engine to be started and warmed up before

making final adjustment.

Final Adjustment: Place governor speed control lever in

"FAST" position. Turn needle valve in until engine

misses (clockwise lean mixture) then turn it out past

smooth operating point until engine runs unevenly (rich

mixture). Now turn needle valve to the midpoint between

rich and lean so the engine runs smoothly. Next, adjust

idle RPM. Rotate throttle counterclockwise and hold

against stop. Adjust idle speed adjusting screw to obtain

1750 RPM. Release throttle engine should accelerate

without hesitation or sputtering. If engine does not

accelerate properly, the carburetor should be re-

adjusted, usually to a slightly richer mixture.

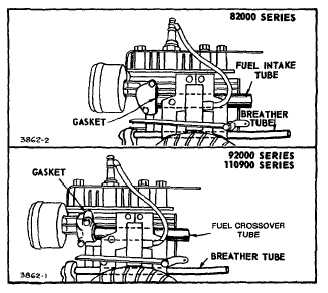

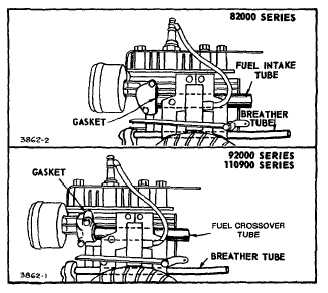

Breather and Fuel Intake Tubes

Breather tube and fuel intake tube thread into the

cylinder on Model Series 82000. Fuel intake tube is

bolted to the cylinder on Model Series 92000, 94000,

110900 and 111900. See Fig. 38. Check for good fit or

damaged gaskets to prevent air leaks or entry of dirt.

Fig. 38 - Breather and Fuel Intake Tubes

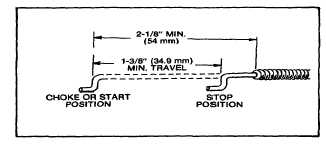

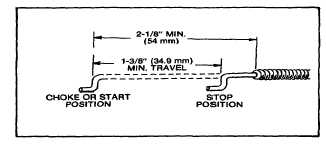

Choke-A-Matlc Adjustment

The Choke-A-Matic feature was standard on Model

Series 82000, 92500 (type nos. lower than 0600) 92900

(type nos. lower than 0500) engines. The remote control

must be of the type in which the control wire moves out

of the casing, when the control lever is moved from the

stop position to the "Choke" or "Start" position. A

minimum travel of 1-3/8" (34.9 mm) is required when the

! remote control is’ mounted, Fig. 39.

Fig. 39- Remote Control

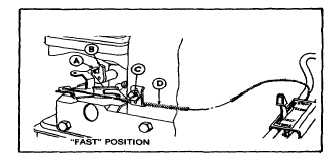

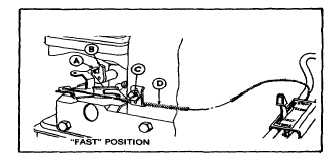

To install remote control assembly proceed as follows:

Remove the air cleaner and move the control lever to a

position about midway between idle and fast. Then

mount the remote control -with the casing clamp as

shown in Fig. 40.

Place control lever on equipment in fast (high speed)

position.

CONTROL

MUST

BE

MOUNTED

ON

EQUIPMENT

TO

MAKE

AN

ACCURATE

ADJUSTMENT. Lever "A" on carburetor should be just

touching choke shaft at "B." Move casing "D" forward or

backwards until correct position is obtained. Tighten

screw

"C."

Recheck

operation

of

controls

after

adjustment, Fig. 40.

Fig. 40 - Choke-A-Matic Control (Typical)

13