TM 5-4240-501-148P

CARBURETION

PULSA-JET

Choke-A-Matic Linkage

Disassembly (Except Model 100900, 130900)

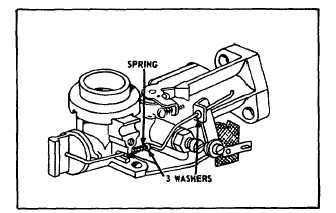

To remove choke link, remove speed adjustment lever

and stop switch insulator plate. Remove speed

adjustment lever from choke link then pull out choke link

through hole in choke slide. Fig. 52.

Fig. 52 - Choke-A-Matic Linkage

Repair

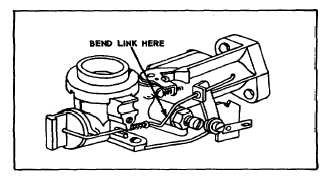

Replace worn or damaged parts. To assemble, slip

washers and spring over choke link. Fig. 53. Hook

choke link through hole in choke slide. Place other end

of choke link through hole in speed adjustment lever and

mount lever and stop switch insulator plate to carburetor.

Fig. 53 - Choke-A-Matic Linkage

Adjust Choke-A-Matic Linkage

The following covers Choke-A-Matic parts installed as a

part of the carburetor assembly. See Section 4 for

Choke-A-Matic remote controls.

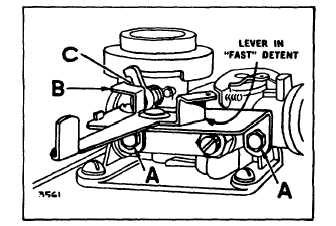

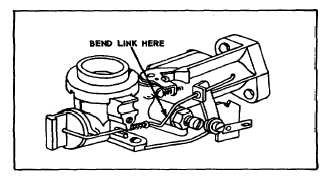

To check operation of Choke-A-Matic linkage, move

speed adjustment lever to choke position. If choke slide

does not fully close, replace link or use fiat nose pliers to

bend choke link. Fig. 54 (Do not overbend.) Speed

adjustment lever must make good contact against stop

switch when moved to stop position.

Fig. 54 - Adjust Choke Link

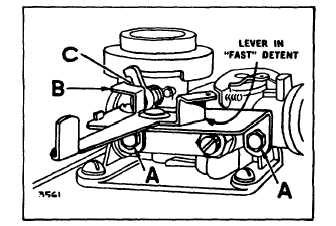

Choke-A-Matic Linkage Model 100900, 130900 and

131900

Manual or remote control for choke and stop is made by

a lever on the control plate mounted to carburetor by two

screws "A", Fig. 55. Lever for remote control has a loose

fit, for manual control, a friction fit. To check lever

action, move to left until it snaps into run detents. Lever

"B" should just touch choke lever at "C."

If it does not, loosen screws "A" slightly and move control

plate to right or left until lever just touches choke lever at

"C." Tighten screws.

Fig. 55 - Choke-A-Matic Linkage Model 100900, 130900,

131900

16