TM 5-4240-501-148P

CARBURETION

Vacu-Jet

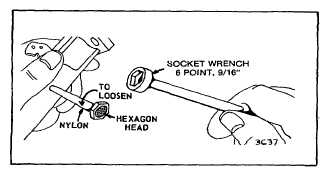

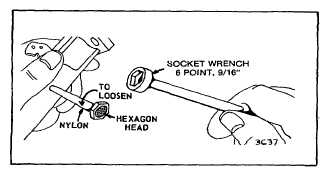

Fig. 64 - Replacing Nylon Fuel Pipe

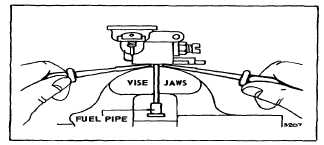

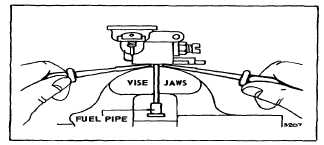

Fig. 65 - Removing Brass Fuel Pipe

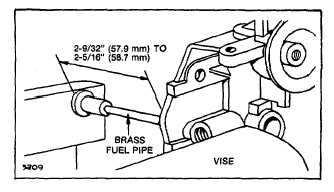

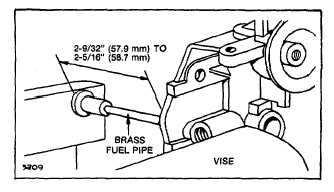

To install brass fuel pipes, remove the throttle, if

necessary, and place the carburetor and pipe in a vise.

Press the pipe into the carburetor until it projects 2-9/32"

(57.9 mm) to 2-5/16" (58.7 mm) from carburetor gasket

surface. Fig. 66.

Fig. 66 - Replacing Brass Fuel Pipe

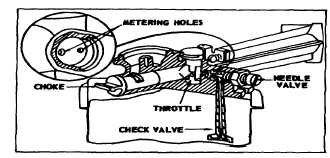

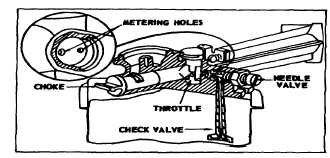

Needle Valve and Seat

Remove needle valve assembly to inspect. If carburetor

is gummy or dirty, remove seat to allow better cleaning of

metering holes. CAUTION: Do not change metering hole

sizes. Fig. 67.

Fig. 67 - Metering Holes

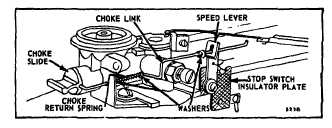

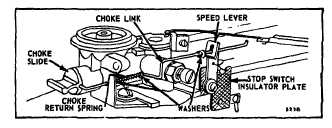

Choke-A-Matic Linkage

Disassemble

To remove choke link, remove speed adjustment lever

and stop switch insulator plate. Work link out through

hole in choke slide. Fig. 68.

Fig. 68 - Choke-A-Matic Linkage

Repair

Replace worn or damaged parts. To assemble

carburetor using choke slide, Fig. 68, place choke return

spring and three washers on choke link. Push choke link

through hole in carburetor body, turning link to line up

with hole in choke slide. Speed adjustment lever screw

and stop switch insulator plate should be installed as one

assembly after placing choke link through end of speed

adjustment lever.

Adjust Choke-A-Matic Linkage

The following covers Choke-A-Matic parts installed on

and as a part of the carburetor assembly. See Section 4

for Choke-A-Matic remote controls. To check operation

of Choke-A-Matic linkage, move speed adjustment lever

to CHOKE position. If choke slide does not FULLY

close, bend choke link. Fig. 69. Speed adjustment lever

must make good contact against stop switch.

19