TM 5-4240-501-148P

CARBURETION

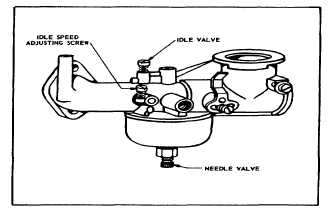

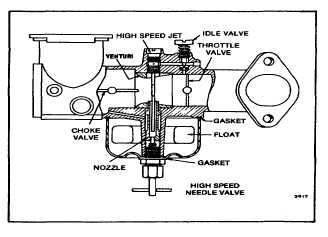

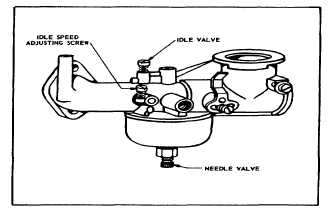

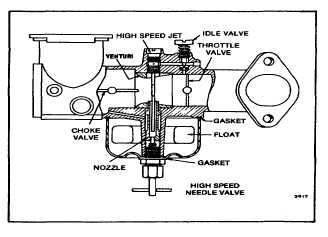

One Piece Flo-Jet

The small one piece Flo-Jet carburetor is illustrated in

Figs. 72 and 73 and was used on Model Series 60700,

61700, 80700, 81700, 140700, 141700, 144700 and

145700. These are float feed carburetors with high

speed and idle needle valve adjustments.

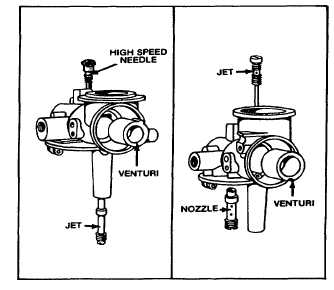

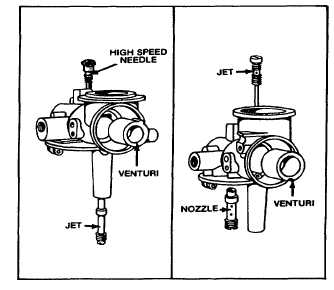

Fig. 74 - Large One Piece Flo-Jet Carburetor

Fig. 75 - Large One Piece Flo-Jet Carburetor

The large one piece Flo-Jet carburetor is similar to the

small one piece Flo-Jet. The main difference is that the

high speed needle is below the float bowl. See Figs. 74

and 75. Repair procedures for small and large Flo-Jet

carburetors are similar except for location of adjusting

needles.

Disassemble Carburetor, Small One-Piece Flo-Jet

Remove idle and high speed adjusting needles. Remove

bowl nut and float bowl. Use screw driver to remove

nozzle. Remove float pin to remove float and float

needle. Use a large wide screw driver to remove float

valve seat.

Disassemble Carburetor, Large One-Piece Flo-Jet

Remove idle mixture needle. Remove high speed

needle valve assembly from float bowl and remove float

bowl. Use a thick blade screw driver to remove nozzle,

then remove jet from top of carburetor. Remove float pin

to remove float and float needle.

Disassemble Continued, Small and Large One-Piece

Flo-Jet

If necessary to remove choke shaft, venturi or throttle

shaft, proceed in following sequence. Pry out welch

plug. Remove choke valve. On carburetors with nylon

choke shafts, remove choke valve as shown in Fig. 78.

Venturi can now be removed, Fig. 77. (Choke-A-Matic

large carburetors have a plate stop pin which must be

pressed out to remove venturi.) To check for throttle

shaft wear, refer to Two Piece Flo-Jet for procedure for

checking.

Fig. 76 - Repair Carburetor

21