tings. These fittings are not shown in the C-124

mately 12 MC-1 tiedown straps at the direction

of the load master. Most of these straps will be

tiedown

template;

therefore,

the

tiedown

pat-

attached to the 1,250-pound cargo tiedown fit-

tern is not shown in figure 4.

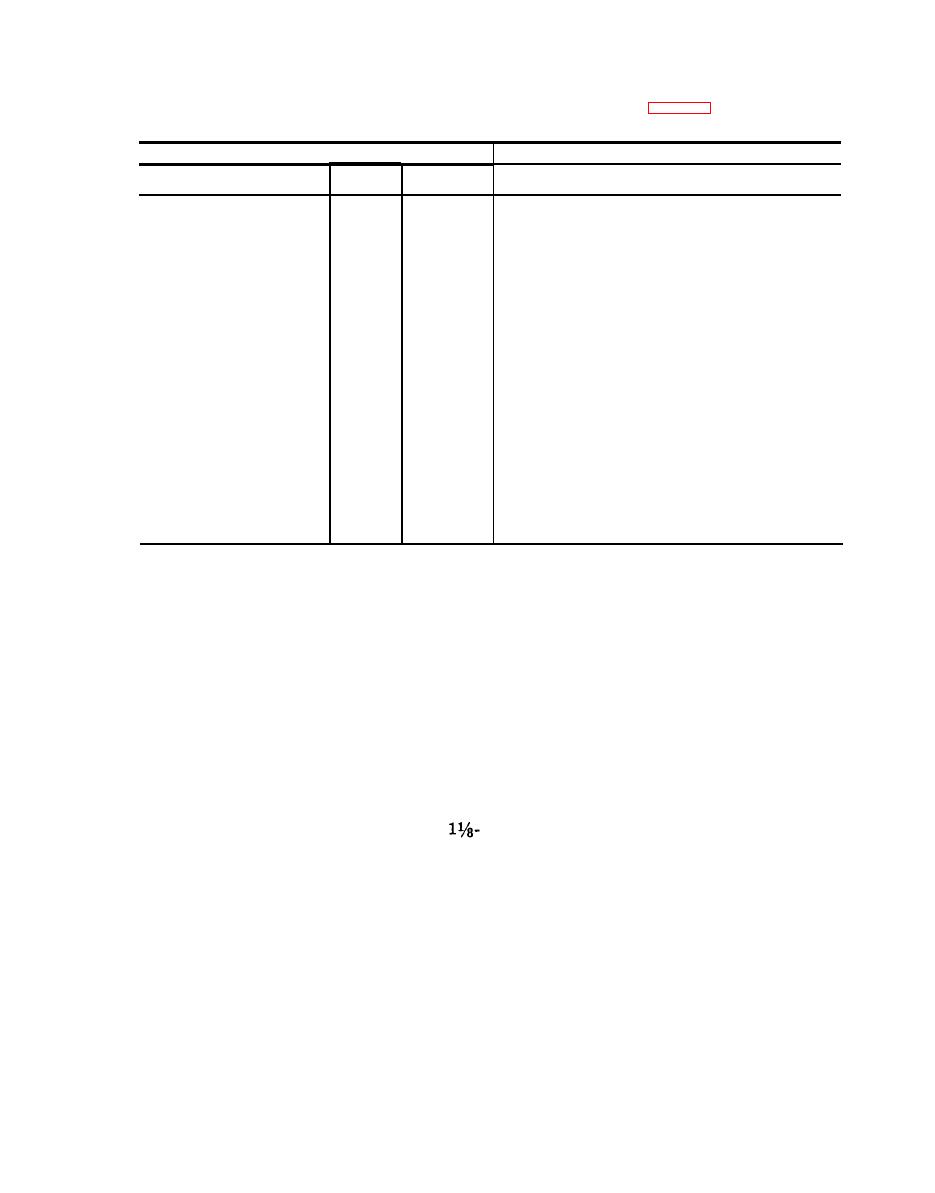

Table 1. Tiedown Data for M578 Recovery Vehicle in C-124-Series Aircraft

Tiedown

device

Tiedown

fitting

Station

Capacity

in

Type

No.

Attach

to

item

device*

1,000 lb

Yellow

236

MB-2

Right

front

lifting

provision.

50

Blue

236

MB-2

Left

front

lifting

provision.

50

Left

front

towing

provision.

Yellow

421

15

MB-1

Blue

421

15

MB-1

Right

front

towing

provision.

MB-1

No.

1

left

road

wheel

arm.

Yellow

450

15

Blue

450

MB-1

No.

1

right

road

wheel

arm.

15

No.

2

right

road

wheel

arm.

Yellow

490

15

MB-1

Blue

490

No.

2

left

road

wheel

arm.

15

MB-1

No.

1

right

road

wheel

arm.

15

Yellow

520

MB-1

MB-1

Blue

520

No.

1

left

road

wheel

arm.

15

MB-2

No.

1

right

road

wheel

arm.

35

Yellow

560

MB-2

Blue

560

No.

1

left

road

wheel

arm.

35

No.

2

right

road

wheel

arm.

Yellow

690

15

MB-1

Blue

590

15

No.

2

left

road

wheel

arm.

MB-1

15

No.

5

right

road

wheel

arm.

Yellow

620

MB-1

Blue

620

No.

5

left

road

wheel

arm.

15

MB-1

35

No.

3

right

road

wheel

arm.

Yellow

660

MB-2

Blue

660

No.

3

left

road

wheel

arm.

35

MB-2

20

Right

towing

and

tiedown

provision.

Yellow

753

MB-2

Blue

753

Left

towing

and

tiedown

provision.

20

MB-2

35

MB-2

Left

towing

and

tiedown

provision.

Green

760

Red

760

35

MB-2

Right

towing

and

tiedown

provision.

*

Type

D-1

tiedown

device

may

be

substituted

for

type

MB-2.

Type

C-2

tiedown

device

may

be

substituted

for

type

MB-1.

g. Attach the item tow bar to the item's front

4.

Off-Loading

left and right towing provision eyes.

a. Remove all

restraining

devices

from

the

h. L o c a t e t h e M 6 2 w r e c k e r a p p r o x i m a t e l y 6 0

item and OVM.

feet from the toe of the aircraft ramp with the

b. R e m o v e

OVM

from

aircraft

by

means

of

M62 winch centered on the item. Connect the

the aircraft loading well platform.

M62 winch cable to the lunette of the tow bar.

c. Lay the shoring as in loading.

Station guides and chock-block men as in load-

d. A s s e m b l e s n a t c h b l o c k s a n d c a b l e a s i n

ing.

loading.

i. W i t h

the

M62

winch,

slowly

winch

the

e. Locate an M35 truck in the position taken

item from the aircraft. The item driver main-

by the M62 wrecker in loading (cable connec-

tains directional control as directed by the front

tion in line with the right-hand section of the

guide and is ready at all times to apply brakes.

aircraft cable.) Connect the aircraft cable and

As the item comes down the ramp, the M35

the M35 winch cable end-to-end with the

operator will apply brakes to keep a restraining

inch pin diameter clevis.

load on the item and to allow the M35 to be

Caution: Use of clevis instead of cable hook

towed forward.

is a safety measure, since the winch towing-

cable has an open throat, and accidental de-

Caution: Because of the structural limita-

tachment might occur if the hook were used.

tions of aircraft components, pulling force in

winching/towing cables must not exceed 30,000

f. R e l e a s e t h e M 3 5 w i n c h a n d b a c k t h e v e h i -

pounds during loading and off-loading. Insure

cle until approximately 40 feet of cable has been

that the aircraft cable does not contact and

run out. Engage and operate the M35 winch

damage

the

aircraft

wall.

until the cable is taut.

AGO 7287A

10