TM 9-2350-238-34-2

6 No leakage is allowed around open port (5), around hydraulic piston (1), or around boom

cylinder head (6).

7 If leakage occurs, disassemble boom control cylinder assembly (2) and check for damaged

parts.

8 If no leakage occurs, reduce pressure and remove hydraulic line or hose (4).

9 Drain hydraulic fluid (item 10, appx B) and plug cylinder ports (3) and (5).

INSTALLATION

l Hydraulic system is under high

pressure. Follow hydraulic

system safety procedures to

prevent injury (TM 9-2350-

238-20-2). Wipe up all spilled

hydraulic fluid.

l Make sure hydraulic system is

depressurized before performing

any hydraulic maintenance to

prevent injury to personnel.

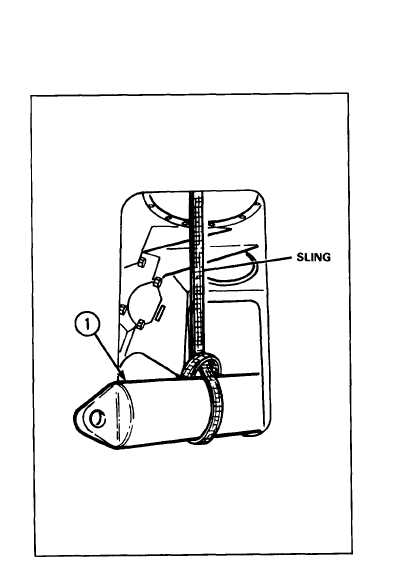

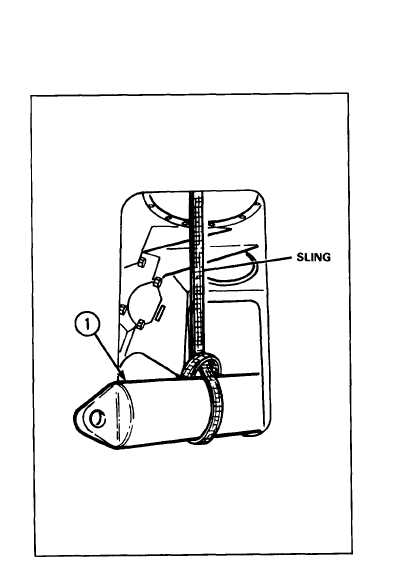

l Use hoist with minimum lifting

capacity of 2000 lb (908 kg) to

prevent injury to personnel and

damage to equipment.

NOTE

l Another M578 Recovery Vehi-

cle or M88A1 Recovery Vehicle

may be used, if available, for

lifting.

l The following steps are written

and illustrated for installation of

one boom winch control

cylinder assembly, but apply to

both .

1 Secure sling around boom winch control

cylinder assembly (1). Lift boom winch

control cylinder assembly and lower

through cab door into place.

2-95