TM 9-2350-256-20-2

0465 00

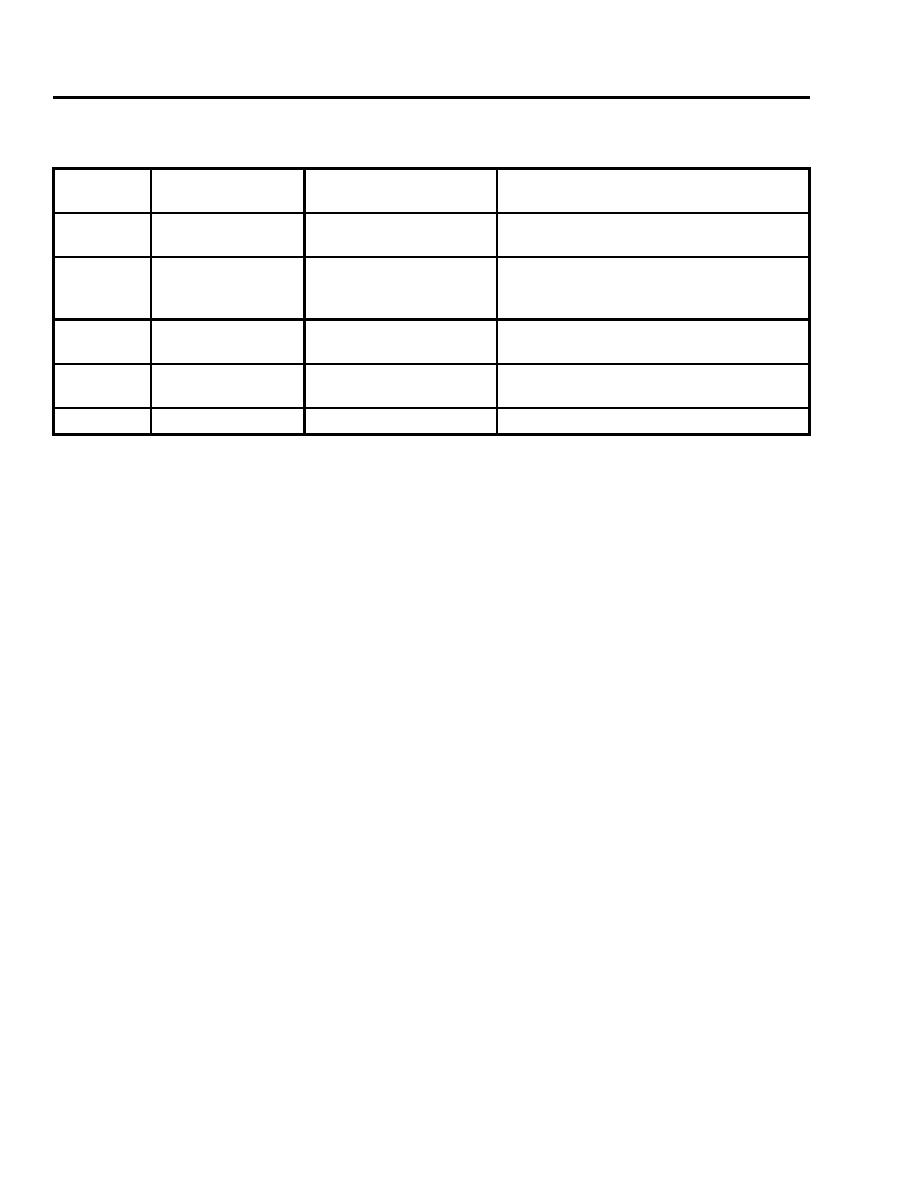

Table 1. Miscellaneous ItemsContinued

Item

Document/Part

National Stock Number

Description

Number

Number

6

ASTM D 3400

Sodium silicate, type 2--

5-gallon (18.9-liter) pail

7

PPP-T-60

--

Tape, adhesive, type I, class I, olive drab number

34087--2 in.- (51 mm-) wide x 60 yard- (54.9 m-)

long roll

8

Tape, insulation, electrical, black--0.50-in.-

(12.7 mm-) wide x 0.010-in.- (0.25 mm-) thick roll

9

DDD-R-30

Wiping rags, cotton, grade B--50 pounds

(22.7 kilograms)

10

GGG-W-665

5120-00-293-1602

Wrench, spanner, universal hose coupling, type V

Cleaning

1.

Clean and dry vehicle thoroughly. Surfaces to be covered with nonhygroscopic tape or sealer must be clean and dry.

Inspection-Acceptance and Rejection Criteria

1.

Perform semiannual Preventive Maintenance Checks and Services (PMCS) (see WP 0096 00).

2.

Inspect drain valves for proper operation and fit. Repair or replace if necessary.

3.

Inspect rubber boots used to seal service brake, steer-and-shift, and accelerator rods at side of bulkhead on sponson. Notify

Direct Support Maintenance to replace boots that are defective or do not provide a watertight fit.

4.

Inspect rubber drain boots on boom for proper seal. Replace if necessary.

5.

Inspect main engine and APU oil filler caps, main engine and APU oil level gages, and transmission filler cap/oil level gage

to ensure watertight fits. Replace if necessary.

6.

Inspect main engine air induction hoses, APU air induction hose, main engine generator air induction hose, and main engine

exhaust cooling hoses. Replace any item found defective.

7.

Inspect cover and gasket on armature and master relays for possibility of leakage. Replace if necessary.

8.

Inspect waterproof electrical connections for possibility of leakage. Replace if necessary.

9.

Inspect personnel door seals for watertight fit. Replace if necessary.

10. Inspect caliber .50 machine gun cover for tears or damage. Replace if necessary.

11. Operate engine and troubleshoot any malfunction or deficiency as required (see WP 0021 00).

Testing

1.

Check release torque of main engine cooling fans (see WP 0144 00).

2.

Check batteries to see that they are fully charged and properly filled with electrolyte. Also, check battery caps for tightness;

battery vents, however, must be open.

Lubrication

1.

Lubricate vehicle in accordance with TM 9-2350-256-10 and WP 0097 00.

END OF WORK PACKAGE

0465 00-2