CHAPTER 12: MAINTENANCE OF MAIN HYDRAULIC SYSTEM

TM 9-2350-256-20

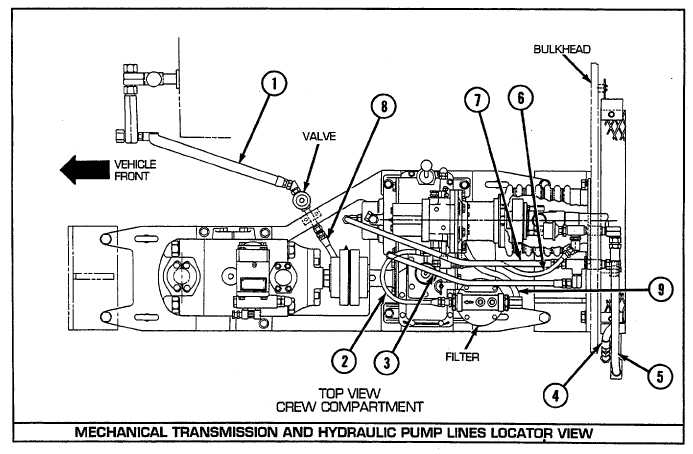

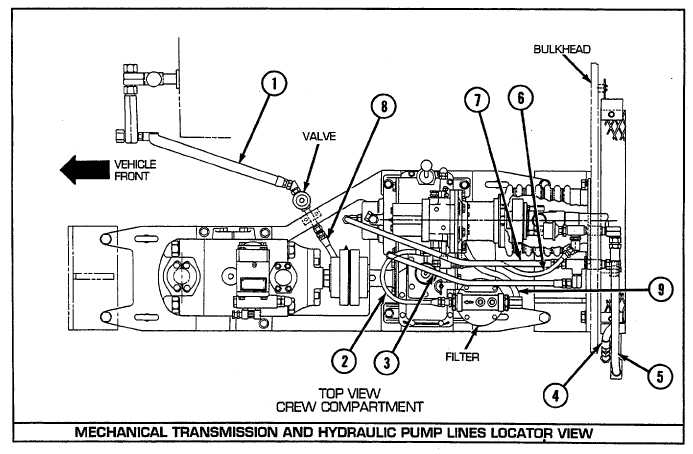

12-1 REPLACE MECHANICAL TRANSMISSION AND HYDRAULIC PUMP

HYDRAULIC LINES AND FITTINGS-Continued

a. REMOVAL

WARNING

Hydraulic fluid under pressure can penetrate skin or damage eyes. Fluid leaks under pressure

may not be visible, use a piece of cardboard or wood to find leaks, but do not use bare hand. Wear

safety goggles for protection. If fluid enters skin or eye, get immediate medical attention.

Do not attempt to loosen or tighten hydraulic fittings or lines when the system is pressurized.

Ensure that the boom is in the stowed position before doing any maintenance on the hydraulic

system.

Do not move under any hydraulically controlled implement when making adjustments or repairs

to hydraulic system. Lower implement and work from above. If implement must be raised for

access, always block to support. If implement drops, injury to personnel can result.

Remove lines and fittings as required using legends, locator views, Table 12-1 for equipment conditions,

Table 12-2 for port routing and the line/fitting illustration as a guide.

1

Hose assembly Code No. 75A

4

Hose assembly Code No. 73

7

Hose assembly Code No. 71

2

Hose assembly Code No. 62

5

Hose assembly Code No. 74

8

Hose assembly Code No. 75

3

Hose assembly Code No. 70

6

Hose assembly Code No. 72

9

Hose assembly Code No. 76

12-2