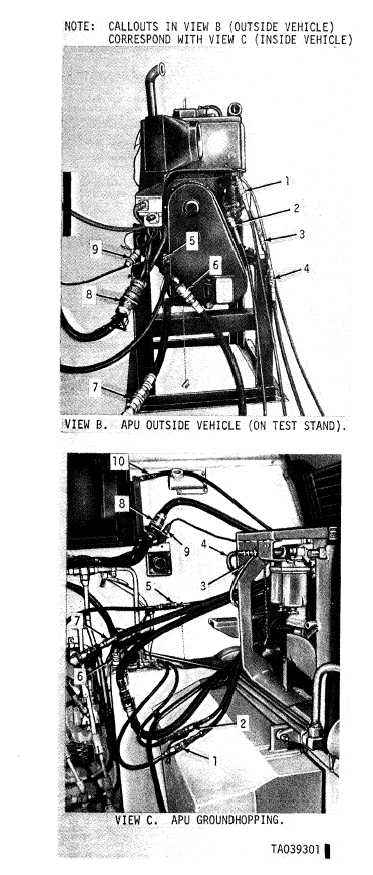

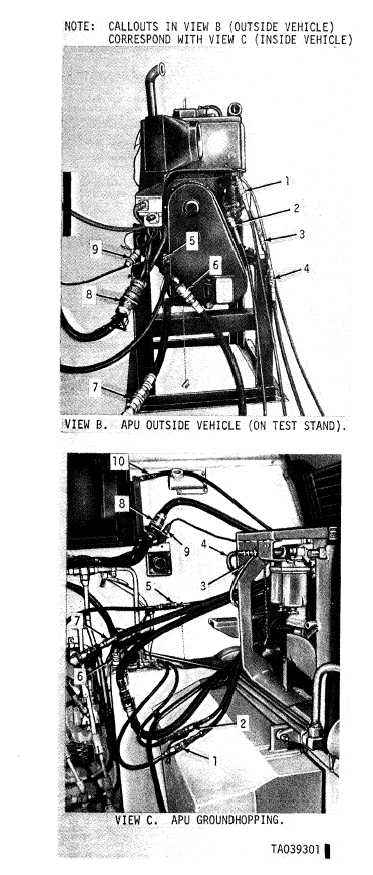

Figure 4-6. Auxiliary power unit test run outside vehicle

(Sheet 2 of 2).

(c) Start the auxiliary

three-minute warmup period

engine and allow a

with no load on the

TM 9-2350-256-34-1

generator or pump. Then check the engine speed

with a hand tachometer or stroboscope. Adjust to

2000 ± 100 rpm, if necessary, in the following man-

ner.

1. Locate the governor speed adjustment

screw on the front of the engine (3, fig. 4-1).

2. Loosen locknut and turn screw slowly

until tachometer or stroboscope reads 2000 ± 100

rpm.

3. Carefully tighten locknut so that the

tachometer or stroboscope reading does not change.

(d) Stop engine, check crankcase oil and fill to

proper level (LO 9-2350-256-12) if required.

(e) Install a pressure gage in the gage port of

the system selector valve on the hydraulic control

panel (subplate) assembly (View A, fig. 2-29).

(f) Start the auxiliary engine, place the

manual shutoff valve in NORMAL OPERATION

position, place the system selector valve in

AUXILIARY position. Check the pressure gage to

confirm a hydraulic load on the auxiliary pump of

2000 ± 50 psi. Adjust the system selector valve

relief valve with the adjusting screw (View A, fig.

2-29), if necessary, to obtain a pressure reading of

2000 ± 50 psi.

(g) Operate the auxiliary engine for 10

minutes with a 2000 ± 50 psi load on the auxiliary

hydraulic pump and no load on the generator.

(h) Check all points for leakage (TM

9-2305-256-20) and correct any other defects.

Return the system selector valve position to the

MAIN position and shut off engine.

(i) Connect a multimeter between the

generator armature terminal and ground (set meter

on DC voltage mode—50 volt range).

(j) DELTED

(k) DELETED

(l) Turn on the generator switch momentarily

and note the generator output voltage on the

multimeter. Voltage should increase slightly when

the generator switch is turned on. If not, remove the

cap from the switching relay box assembly in the

vehicle. Loosen the rheostat locking nut and turn

the adjusting screw slowly clockwise until the

voltage on the multimeter increases slightly. If

voltage does not increase, troubleshoot the system.

I

NOTE

Current limiter rheostat must be

calibrated when the auxiliary power unit

is reinstalled in the vehicle.

(m) Turn off generator.

(n) Turn off engine.

(3) Test inside vehicle.

(a) Make sure that all lines, cables, ac-

cessories and other components are properly in-

stalled, tightened and adjusted. Fill chain case and

crankcase to the proper levels (LO 9-2350-256-12)

if required.

Change 2

4-20.3