TM 9-2350-256-34

0026 00

5.

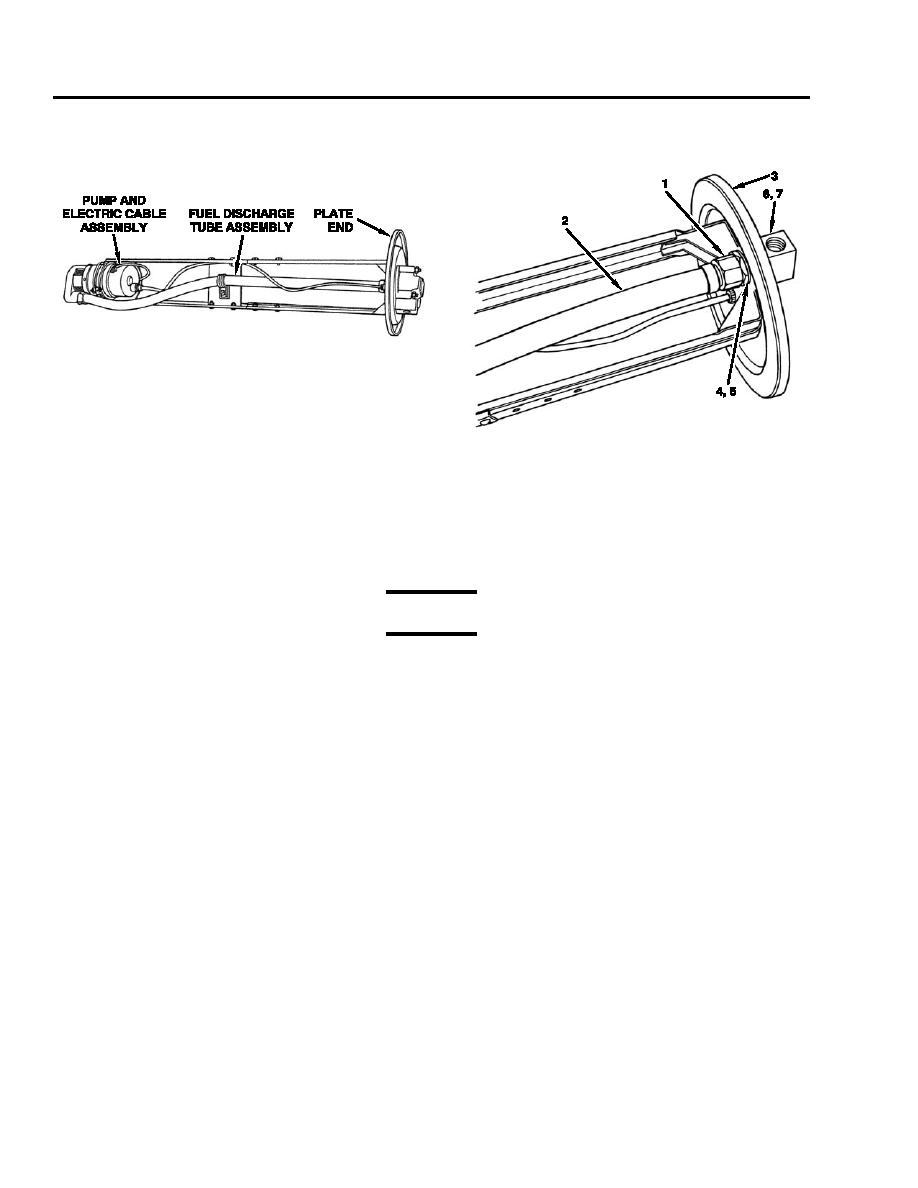

Install packing (7), discharge fitting (6), lockwasher (5), and hexagon nut (4).

6.

Install discharge tube (2) to cover plate (3) by tightening jamnut (1).

NOTE

Refer to TM 9-2350-256-20 for assembly instructions for the terminal assembly.

Test and Inspection

WARNING

Vapor can explode from electric arc. Do not operate pump by connecting or disconnecting clips. Use a

switch (refer to no. 8 on illustration below) in the line.

NOTE

To determine polarity of the terminal assembly pins, face the pump and mount assembly so that the

discharge fitting is to the right and the terminal to the left with the long center (polarizing) pin at the top

of the terminal and the screw at the bottom. The positive (hot) pin is on the left side of the terminal and

the negative (ground) pin is on the right side.

1.

Assemble test equipment to pump with switch (refer to no. 8 on illustration below) open and submerge pump in test fluid

(fuel VV-F-800) so that test fluid covers pump by at least 2 in. (51 mm).

2.

Adjust power supply for 27.5 0.1 V dc. Close switch (refer to no. 8 on illustration below) and readjust power supply if

necessary.

3.

Operate pump at 27.5 V dc. Rated flow should be 220 9 gph (3.67 0.15 gpm) (832.8 34.1 L/h) at 3.75 psi (25.9 kPa).

4.

Repeat step 2 for an 18 + 0.1 V dc power supply.

5.

Operate pump at 18 V dc. Rated flow should be 80 3 gph (1.33 + 0.05 gpm) (302.8 11.4 L/h) at 2.50 psi (17 kPa).

0026 00-4