TM 9--2350--292--20--1

0187 00--147

0187 00

PREVENTIVE MAINTENANCE CHECKS AND SERVICES INCLUDING

LUBRICATION INSTRUCTIONS -- CONTINUED

TABLE 3 PREVENTIVE MAINTENANCE CHECKS AND SERVICES

INCLUDING LUBRICATION INSTRUCTIONS, SEMIANNUALLY -- CONTINUED

ITEM

NO.

NOT FULLY

MISSION

CAPABLE

IF:

PROCEDURE

LOCATION

ITEM TO

CHECK/

SERVICE

INTERVAL

SEMIANNUALLY

EXTERIOR

56

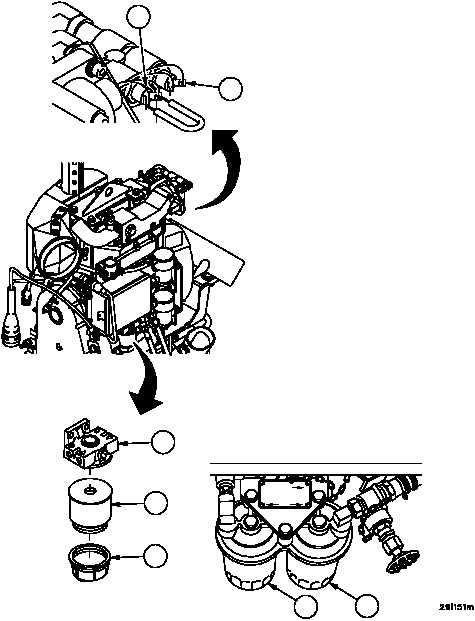

Auxiliary Power

Unit (HATZ) --

Continued

c. Replace primary fuel filter (4)

(WP 0609 00).

d. Replace secondary fuel filter (5)

(WP 0609 00).

Any fuel

leaks.

e. Remove bottom cap (6) of fuel/water

separator (7) then remove and replace

fuel/water separator filter element (8) and

install bottom cap (6).

f. Tighten fuel and oil connections that

leak.

g. Inspect air system components;

replace if damaged or deteriorated.

h. Service air cleaner. Check for

cleanliness and obstructions. Replace filter

if damaged (WP 0608 00)). Clean if dirty

(TM 9--2350--292--10).

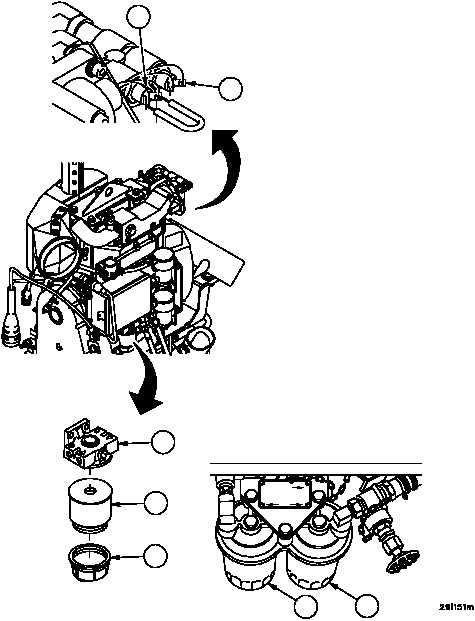

i. Start APU engine (TM

9--2350--292--10). Listen for unusual

noises in engine and generator which

might indicate improper operation.

j. Observe warning lights and oil pressure

gauge to see if unit is functioning properly

(TM 9--2350--292--10). Oil pressure gauge

should indicate approximately 55 to 80 psi

(368 to 551 kPa). Shut off engine.

k. Remove adhesive from thermostatic

switch S1 (9). Using a jumper wire, short

the terminals of thermostatic switch S1 (9)

and observe the sump fan operation.

Apply adhesive (item 25, WP 0716 00) to

exposed terminals of switch S1 (9).

l. Remove adhesive from thermostatic

switch S2 (10). Using a jumper wire, short

the terminals of thermostatic switch S2

(10) and observe the door fan operation.

Apply adhesive (item 25, WP 0716 00) to

exposed terminals of switch S2 (10).

9

10

EMERGENCY FUEL

SHUT-- OFF

PRIMARY SECONDARY

FUEL FILTERS

AUX. POWER UNIT

5

4

6

8

7

Dirty or

obstructed

air cleaner.

Any unusual

noises.

Malfunctioning

lights or low

pressure.

Door fan or

sump fan

does not

operate.