TM 10-1670-262-12&P

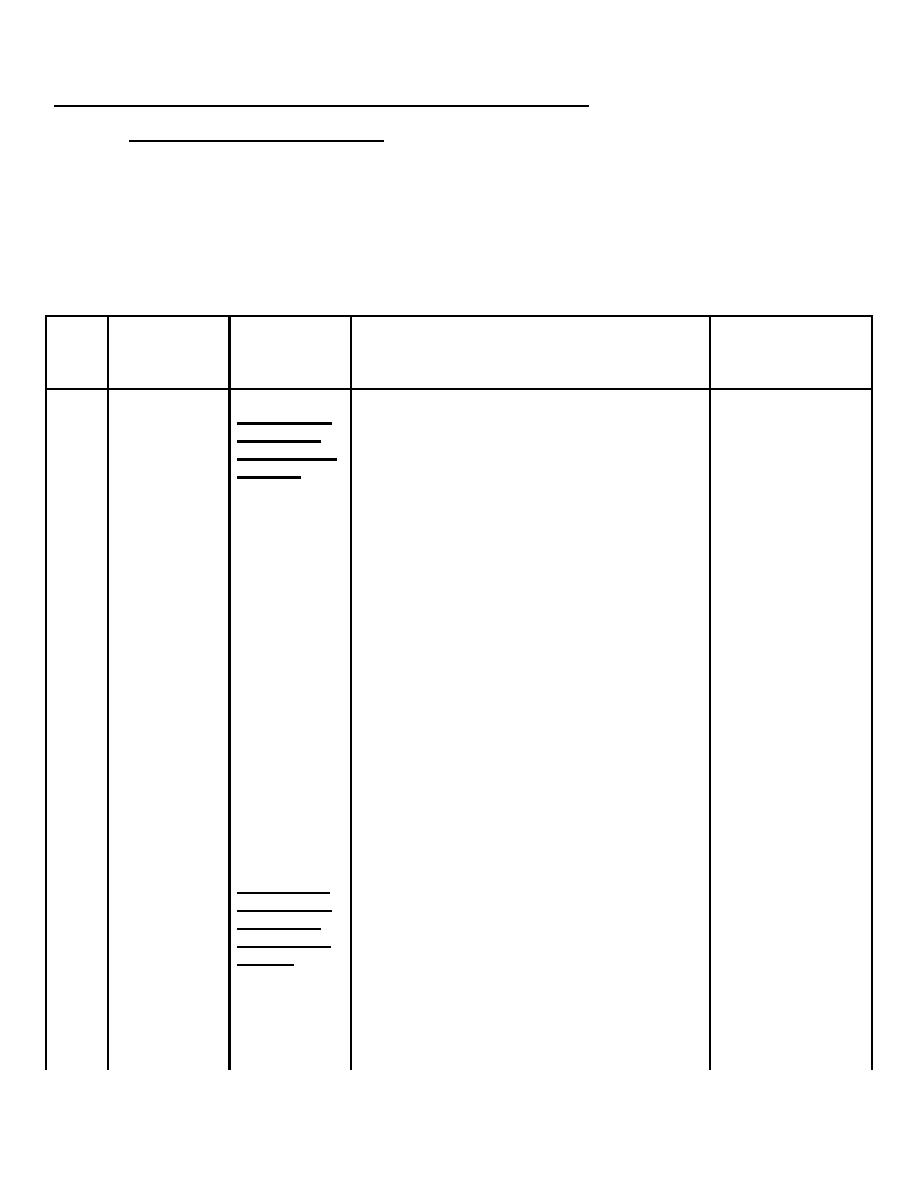

2-3. Operator's Preventive Maintenance Checks and Services - continued.

f.

Not Fully Mission Capable If: Column. This column contains the criteria that will cause the equipment to be

classified as not fully mission capable because of inability to perform its primary mission. An entry in this column:

(1)

Identifies conditions that make the equipment not fully mission capable for readiness reporting

purposes.

(2)

Denies use of the equipment until corrective maintenance has been performed.

Table 2-1. Operator Preventive Maintenance Checks and Services

Location

Item to

Item

Check/

Not fully mission

No.

Interval

Service

Procedure

capable if:

PERSONNEL

INSERTION

EXTRACTION

SYSTEM

1

Before

Harness

Inspect for broken or missing stitching;

Components are

frayed, worn, or cut webbing; bent, broken,

damaged or

rusted, or missing hardware.

missing.

2

Before

Suspension

Inspect for cuts, abrasions, melting, or

Components are

Rope

fuzzing; bent, broken, rusted, or missing

damaged or

snap hooks.

missing.

3

Before

Safety Rope

Inspect for cuts, abrasions, melting, or

Components are

fuzzing; bent, broken, rusted, or missing

damaged or

snap hooks; burrs or foreign materials on

missing.

snap hooks.

4

Before

Bridle

Inspect for broken, loose, or missing

Components are

stitching; frayed, worn, or cut webbing;

damaged or

bent, broken, rusted, or missing hardware.

missing.

5

Before

Deployment

Inspect for broken, loose, or missing

Components have

Bag

stitching; broken or damaged web loops;

tears, dirt, grease,

holes and tears; dirt, grease, or foreign

foreign material, or

material.

damaged stitching.

CARGO AND

PERSONNEL

LOWERING

ANCHORING

DEVICE

6

Before

Web Loop

Inspect for broken or missing stitching;

Components are

frayed, worn, or cut webbing; bent, broken,

damaged or

rusted or missing hardware, burrs on

missing.

hardware; connector snap operation; dirt,

oil, grease on webbing.

2-2