TM 5-4240-501-14&P

THEORIES OF OPERATION

Ignition

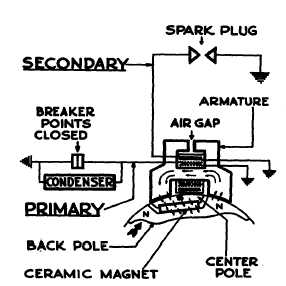

Figure 27.

Fig. 27 shows the flow of magnetism through the iron

core of the coil as the magnet in the flywheel approaches

the armature. The arrows indicate the direction of flow of

the magnetic field. You will notice that there is no (or

very little) magnetism flowing through the upper part of

the core. This is because of the air gap at the top which

causes a resistance. In this position our breaker points

close.

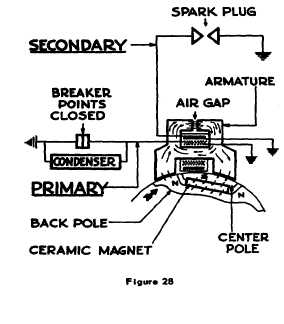

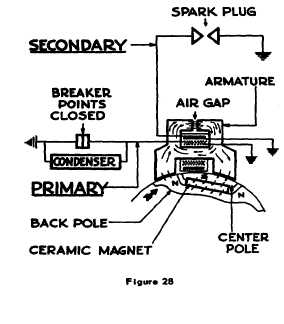

Figure 28.

The flywheel continues to rotate to the position shown in

Fig. 28. The magnetism continues to flow in the same

direction and magnitude through the center of the core

because of primary current. However, the magnetism

flows in an opposite direction through the outer portion of

the core and through the top air gap because of the

change of flywheel position. Since the shunt air gap

provides a path for the flux from the armature legs and

the core, the required current flow through the primary

circuit is low, assuring long breaker point life.

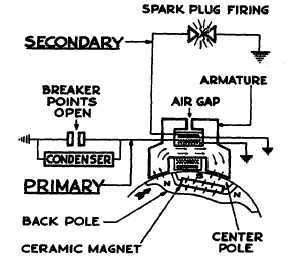

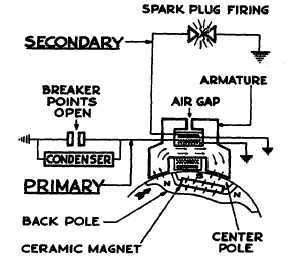

Figure 29.

At this position our breaker points open, the current

stops flowing in the primary circuit and therefore the

electromagnetic

effect

ceases.

The

magnetism

instantaneously changes from the flow shown in Fig. 28

to that shown in Fig. 29. Note the opposite direction of

the arrows indicating a complete reversal of magnetism

which has happened so fast that the flywheel magnet

has not had a chance to move any noticeable amount.

The rapid change in magnetism produces 170 volts in

the primary winding. A voltage is also induced in the

secondary but it is in proportion to the turns ratio, i.e., 60

to 1 or 10,000 volts. This voltage is more than ample to

fire across the spark plug electrodes. This rapid

magnetism change is very short and therefore the flow of

current across the spark plug gap is as long as

necessary, but short enough to afford long electrode life.

Thus we achieve our aims of full power plus long life and

dependability.

15

14