TM 5-4240-501-14&P

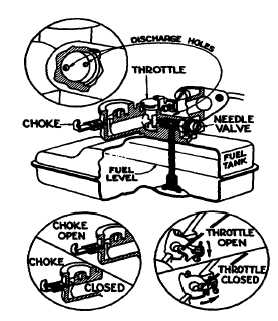

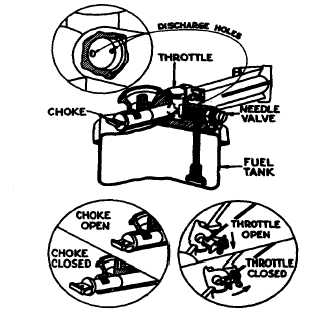

Since no accelerator pump is used on this carburetor

and since many of these engines are used on lawn

mowers where rapid acceleration is needed, the mixture

should be rich. Turn the needle valve in until the engine

begins to lose speed, indicating a lean mixture. Then,

open the needle valve past the point of smooth operation

until the engine just begins to run unevenly. Since this

setting is made without load, the mixture should operate

the engine satisfactorily under load.

These carburetors do not have an idle valve, but the

mixture at idle speed is controlled in a different way. As

the throttle closes to idle, the leading edge takes a

position between the two discharge holes. The larger of

the discharge holes is now in the high pressure area, and

the flow of fuel through it will cease. The small hole will

continue to discharge fuel but the amount will be

metered by the hole size and will be in proportion to the

reduced air flow. For this reason it is important that the

small discharge hole be of the proper size. The needle

valve will allow much more fuel to pass than should go

through the small discharge hole. A number 68 drill can

be used as a plug gauge to check the small hole. A

number 56 drill can be used to check the larger hole.

This can be done with the needle valve and seat

removed. See Fig. 20.

Figure 20.

THEORIES OF OPERATION

Carburetion

You will notice a small section is milled out of the throttle

where it meets the discharge hole. This concentrates the

flow of air past the hole and assures good vaporization.

The idle speed adjusting screw should be set to obtain

an idle speed of 1750 RPM. This may seem fast to

people accustomed to auto engines, but it is necessary

in order to have fast acceleration. It also helps cooling

and lubrication.

A slight unevenness may be noticed at idle speed, but

this is normal and no readjustments of the needle valve

should be made.

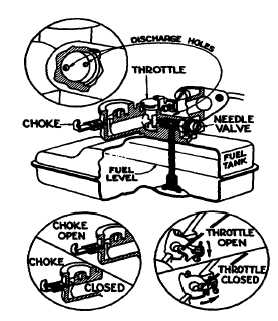

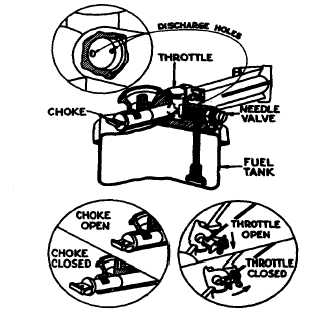

The choke is the sliding plate mounted at the outer end

of the carburetor. Fig. 20 and 21. The choke is pushed

in to close the air intake for starting but should be pulled

out as soon as the engine starts. The use of this choke

should be understood clearly. Many complaints of

engine trouble, upon investigation prove to be nothing

more than failure to properly use the choke, especially

where the choke is operated by a remote control. The

choke must close fully.

Figure 21.

The latest engines with Vacu-Jet carburetors incorporate

a ball check in the fuel pipe which assures a steady flow

of fuel to the needle valve and discharge holes.

11

14