TM 5-4240-501-14&P

THEORIES OF OPERATION

Compression

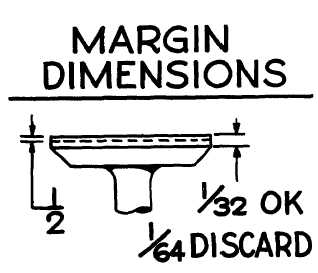

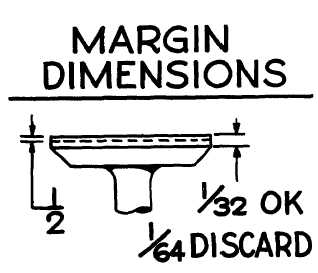

Figure 10.

The margin on a new Briggs & Stratton valve is 1/82 of

an inch, so that when it becomes less than 1/64 of an

inch the valve should be discarded. Remember, this is

after all pit marks and burn marks have been removed

from the valve face. If the valve is bent, the face will be

ground unevenly, and if the margin becomes too thin on

one side the valve should also be discarded. A valve

with too thin a margin will not be able to withstand the

heat and will quickly crack and burn. After facing the

valves and the valve seats to a 45° angle, place a little

fine grinding compound on the valve face, and very

lightly lap the valve to the seat. Use of fine grinding

compound removes any grinding marks and gives a

clear picture of the valve seat width. Be sure to remove

all grinding compound from seat and valve.

Figure 11.

The valve seat width is usable up to 5/64 of an inch, but

a new seat should be between 3/64 and 1/16 of an inch,

and it should be in the center of the valve face. After the

valve seat and faces are ground, the valve should be

installed in the guide, the cam gear turned to the proper

position, and the tappet clearance checked. Refer to

Repair Instructions for tappet clearance. Usually the

clearance will be too small, and the end of the valve

stem will have to be ground off to obtain the proper

clearance. Care should be taken not to overheat the end

of the valve stem while this grinding is taking place; be

sure the end is square with the stem. It is recommended

that the valve springs and retainers be assembled

immediately after setting the tappet clearance to prevent

chances of dirt getting under the valve seat.

6

14