TM 5-4240-501-14&P

THEORIES OF OPERATION

Compression

Figure 6.

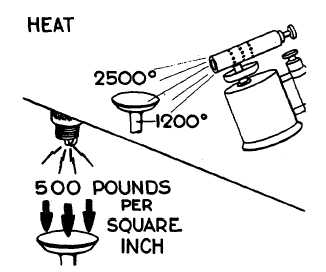

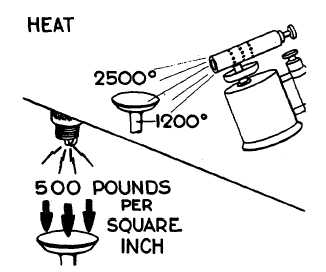

Valves have to seal well enough to stand pressures up to

500 pounds per square inch. Under full load, the

exhaust valve is exposed to temperatures high enough

to cause it to operate at a red heat. The temperature of

the valve under these conditions may be 12000 F. or

more. The intake valve is cooled by the incoming

mixture. The exhaust valve is subjected to high

temperature exhaust gases passing over it on their way

out of the cylinder. It is, therefore, very difficult to cool

the head of the exhaust valve. The cylinder head, the

cylinder, and the top of the piston are exposed to this

same heat, but these parts are cooled by air from the

flywheel fan and oil from the crankcase. Very special

steel is required in the exhaust valve to enable it to

withstand the corrosive action of the high temperature

exhaust gases.

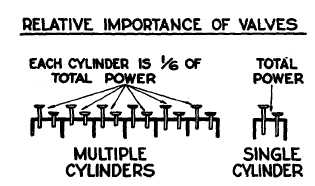

Figure 7.

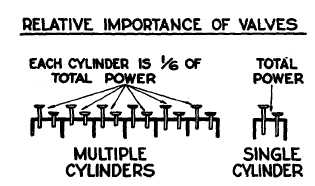

Remember again that the Briggs & Stratton engine is a

single cylinder engine with two (2) valves as compared to

the customary 12 or 16 valves in an automotive engine.

The fewer the valves, the more important they become.

In a 1 cylinder engine one bad valve can cause a great

drop in horsepower or cause the engine to stop entirely.

In a multicylinder engine, one valve may fail and only

1/6th or 1/8th of the power is affected as the bad cylinder

may be motorized by the other good cylinders. Hence,

good valve condition is even more important in 1 cylinder

engines than it is in multicylinder engines.

Now if the valves and seats are so important, how do we

do a good valve job on a Briggs & Stratton engine?

The first requirement is good equipment. A valve

refacer and valve seat grinders are necessary. If you do

not have them, arrangement should be made with your

local Briggs & Stratton dealer.

After the valves are removed, they should be thoroughly

cleaned on a wire hrush wheel to remove all carbon

deposits. You will find sometimes it is easier to polish

carbon than to remove it, but it must come off. Also,

remove carbon from valve guides. When the valves are

clean, they should be visually inspected.

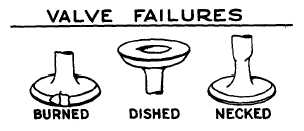

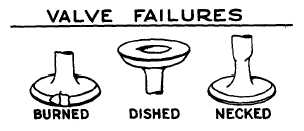

Figure 8.

As mentioned above, when a valve becomes defective in

a multicylinder engine, the bad cylinder is motorized by

the other cylinders. This may cause serious damage to

the valve and seat. Briggs & Stratton engine valves are

seldom subjected to the extremes of abuse that

automotive valves are. While valves may burn to some

extent, it is very seldom that a valve seat or face is very

badly burned. Dished or necked valves are almost never

found.

4

14