TM 5-4240-501-14&P

Valve seat burning is usually caused by an accumulation

of carbon or fuel lead either on the valve stem or on the

valve face, or from insufficient tappet clearance. These

deposits on the valve stem or on the face will hold the

valve open, allowing the hot flames of the burning fuel to

eat away the valve face and seat. A dished valve is one

that has a sunken head. This is caused by operating at

too high a temperature with too strong a spring, or the

head can be eroded away by highly leaded fuels. A

necked valve is one that has the stem directly beneath

the head eaten away badly by heat or where the stem

has been stretched.

Valve sticking is caused by fuel lead, gum or varnish

forming on the valve stem and in the valve guide. We

believe that most of the deposits formed are caused by

carbon, fuel lead, or gum. Since the amount of lead in

different fuels varies, the rate of deposit build-up

naturally will vary. When an exhaust valve no longer

closes properly, due to excess deposits, the hot gases

escaping from the combustion chamber heat up the

valve stem and guide excessively. This causes the oil on

the valve stem to oxidize into varnish which holds the

valve partially open and causes burning. Intake valve

sticking may be caused by the use of fuels having an

excessively high gum content. Fuels that are stored for

too long a period of time may contain high amounts of

gum. -

If burning occurs in a rather limited area on the valve

face, it indicates that something may have caused the

valve to tip. This could be due to a bent valve stem or a,

deposit on one side of the valve seat or stem.

Such a condition would leave an opening for the passage

of hot exhaust gases which could burn the valve so badly

that it could not be refaced. These valves must be

discarded.

THEORIES OF OPERATION

Compression

Figure 9.

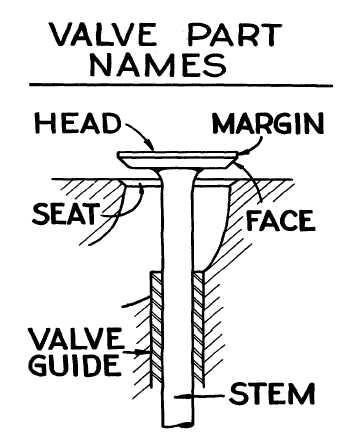

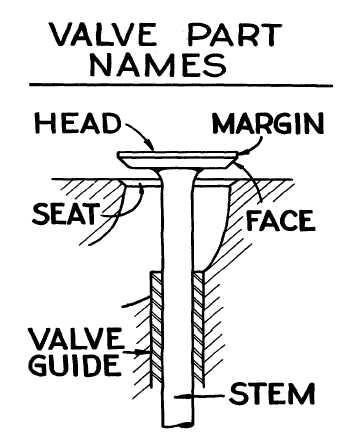

The important parts of a valve are the head, the margin,

face, and stem. They make contact with the seat and

the valve guide in the cylinder. The margin is the edge of

the valve head. As a general rule, the valve should be

discarded when the margin becomes less than one-half

of the original thickness.

5

14