TM 5-4240-501-14&P

THEORIES OF OPERATION

Carburetion

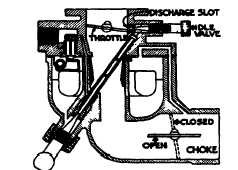

The idle valve chamber leads into the carburetor throat

above the throttle. Here the pressure is low, and the fuel

rises in the nozzle past the idle valve and into the

carburetor throat through the discharge slot. The

amount of fuel is metered by turning the idle valve in or

out until the proper mixture is obtained. Here again we

see what happens if the needle is screwed in too far. A

damaged idle valve can result.

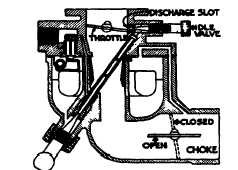

Adjustment of the idle valve is similar to that of the

needle valve but should be made after the needle valve

has been adjusted. The idle speed is not the slowest

speed at which the engine will run. On small engines it is

1750 RPM. On larger engines the idle speed may be as

low as 1200 RPM. Use a tachometer to set the speed.

Turn the idle speed adjusting screw (located on throttle

shaft) until the desired idle speed is obtained and hold

throttle closed. Turn the idle valve in until speed

decreases, then out until speed increases and again

decreases. Then turn the idle valve to a point midway

between these two settings. Usually the idle speed

adjusting screw will have to be reset to the desired idle

speed.

Figure 18.

The next problem is starting the engine in different

temperatures and with different fuels. A butterfly,

mounted on a shaft, is placed in the air horn. With this

choke we can close, or almost close, the air horn and get

a low pressure area in the venturi and throat. See Fig.

18.

Thus, a rush of fuel is obtained from the nozzle with a

relatively small amount of air. Even with low vaporization

this extra rich mixture will give easy starting. Only a

portion of the fuel will be consumed while choking, and a

large portion will remain in the cylinder. This raw

gasoline will dilute the crankcase oil and may even cause

scuffing due to washing away of the oil film from between

the piston rings and the cylinder wall. For this reason,

prolonged choking should be avoided.

This now is our complete carburetor.

VACU-JET CARBURETORS OR

SUCTION FEED

Now let us take a look at the Vacu-jet or suction feed

system. Here the fuel tank is below the carburetor, so

obviously the fuel will not flow by means of gravity.

Therefore, the force of atmospheric pressure must be

employed.

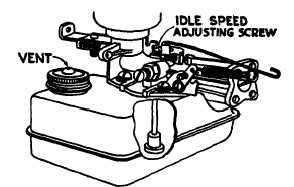

Figure 19.

Again we have a vent hole in the fuel tank cap to allow

the pressure in the tank to remain constant. Now here is

something important. Before adjusting the carburetor

pour in enough fuel to HALF fill the tank. The distance

the fuel has to be lifted will affect the adjustment. At half

full we have an average operating condition, and the

adjustment will be satisfactory if the engine is run with

the tank full or nearly empty.

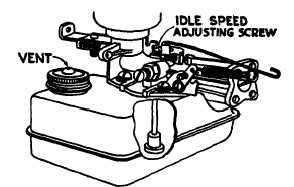

As the piston goes down in the cylinder with both the

intake valve and the throttle open, a low pressure area is

created in the carburetor throat. A slight restriction is

placed between the air horn and the carburetor throat at

the choke. This helps to maintain the low pressure.

The difference in pressure between the tank and the

carburetor throat forces the fuel up the fuel pipe, past the

needle valve, through the two discharge holes. The

throttle is relatively thick, so we have, in effect, a venturi

at this point, thus aiding vaporization. A spiral is placed

in the throat to help acceleration and also to help keep

the engine from dying when the throttle is opened

suddenly.

The amount of fuel at operating speed is metered by the

needle valve and seat. Turning the needle valve in or

out changes the setting until the proper mixture is

obtained. This adjustment must always be done while

the engine is running at operating speed, not at idle

speed. While the needle valve may look like an idle

valve due to its position, it is a true high speed mixture

adjusting valve.

10

4