TM 9-2350-256-34-1

2 - 4 3 . H y d r a u l i c O i l T a n k C o v e r A s s e m -

b l i e s a n d S u c t i o n P i p e

a. Hydraulic Oil Tank Top Couer Assemblies.

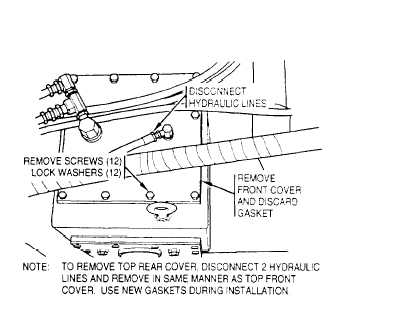

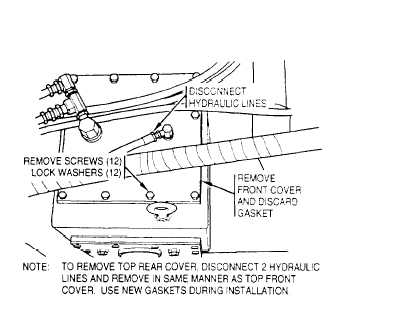

(1) Removal. Prior to removing the oil tank front

and rear top cover assemblies, remove subfloor plates

9, 10, 11 (fig. 2-3), disconnect five hydraulic lines

(View C, fig. 2-39) and remove fittings (TM 9-2350-

256-20). Remove the oil tank top cover assemblies as

shown in figure 2-42.

(2) Installation. Install the hydraulic oil tank

front and rear top cover assemblies in reverse order of

removal.

b. Hydraulic Oil Tank Front Cover Assembly.

(1) Removal. Prior to removing the oil tank front

cover assembly, remove subfloor plate 11 (fig. 2-3),

dram the tank below the level of the cover, disconnect

hydraulic lines (View A, fig. 2-39) and remove fittings

(TM 9-2350-256-20). Remove the oil tank front cover

assembly in the same manner as the top cover assem-

blies (fig. 2-42).

(2) lnstallation. Install the oil tank front cover as-

sembly in reverse order of removal and fill tank (TM

9-2350-256-20).

Figure 2-42. Hydraulic oil tank top covers - removal and installation.

c. Hydraulic 0i1 Tank Suction Pipe.

(1) Removal. The suction pipe is located inside the

oil tank directly behind the oil filter. Prior to removing

the suction pipe, drain the oil tank below the level of

the filter and remove the top rear tank cover (a above).

Remove four screws and lock washers and the two split

flanges holding the suction pipe. Remove the suction

pipe and packing.

(2) Installation. Install the suction pipe and pack-

ing in reverse order of removal and refill the tank (TM

9-350-256-20).

2 - 4 4 . F o r w a r d F u e l T a n k A s s e m b l y

NOTE

The tank may be stripped of all fittings, fuel

- pump and sending unit, while installed, for

ventilation purposes (TM 9-2350-256-20).

a. Prior Operations. Prior to removal of the forward

fuel tank, perform the following operations:

(1) Remove commander’s and rigger’s seats, hoist

winch cable chute and the drain valve controls and

control lever bracket (TM 9-2350-256-20). Remove

subfloor plates 3. 5, 9, 10, 11, 12. 13, 14, 17, 18, 20.

21, 22 and 24 (fig. 2-3).

(2) Remove main winch and spade assembly (para

2-25) and hoist winch assembly (para 2-35). Remove

mechanical transmission and hydraulic pump assem-

bly (para 2-32) and hydraulic system oil tank assembly

(para 2-40).

(3) Disconnect mechanical transmission power

takeoff drive shaft at main engine and remove shaft

entirely (fig. 2-30).

(4) Remove auxiliary power unit control box and

bracket and the shift and throttle control components

mounted on floor plates (TM 9-2350-256-20). Re-

move any stowage racks and boxes interfering with re-

moval of the tank (TM 9-2350-256-20).

(5) Support rear (lower) end of hydraulic control

panel (subplate) by opening operator’s and mechanic’s

hatches and looping a chain through the hatches.

Secure the chain to lower end of panel to support it.

Remove attaching bolts at rear support bracket and re-

move subfloor plate 1 (fig. 2-3).

b. Remoual. Remove the forward fuel tank assembly

as shown in figure 2-43.

2-74

Change 8