TM 9-2350-256-34-1

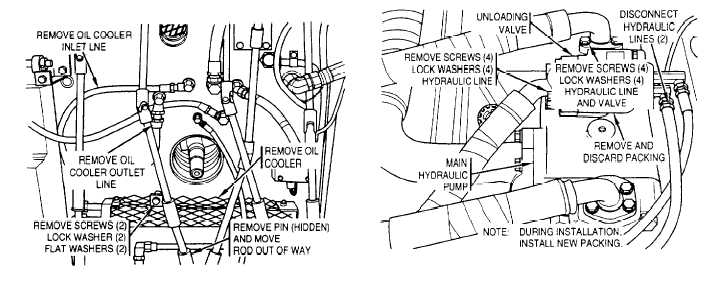

Figure 2-32. Mechanical transmission oil cooler assembly

and lines-removal and installation.

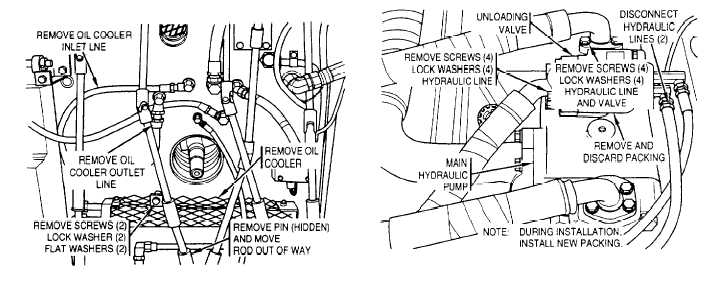

Figure 2-33. Main hydraulic pump unloading valve -

removal and installation.

N O T E

b . I n s t a l l a t i o n . I n s t a l l t h e m e c h a n i c a l t r a n

smission oil cooler assembly and lines in reverse or-

der of removal.

2-34. Main Hydraulic Pump Unloading Valve

P r i o r t o r e m o v i n g t h e m a i n h y d r a u l i c p u m p

unloading valve, remove subfloor plates 11, 12 and

14 (fig. 2-3) Remove and install the main hydraulic

pump unloading valve as shown in figure 2-33.

I f y o u r v e h i c l e h a s h o i s t w i n c h

a s s e m b l y 8 7 3 9 0 0 9 - 1 1 o r 8 7 3 9 0 0 9 - 1 ,

s e n d

w i n c h

a s s e m b l y

t o d e p o t

m a i n t e n a n c e f o r r e m o v a l o f a n t i -

c h a t t e r k i t .

2-35. Hoist Winch Assembly

a. Removal. Prior to removing the hoist winch

assembly, remove the hoist winch cable (para 2-231.

Remove the cupola and cupola plate. commander’s

s e a t

a n d h o i s t w i n c h c a b l e c h u t e ( T M

9-2350-256-20,. Remove any oddment trays. racks

and baskets, as required. to allow clearance and

prevent damage. Remove subfloor plates 4, 5, 11,

17, 18, 19, 20, 21. and 24 (fig. 2-3). Remove hoist

winch assembly as shown in figure 2-34.

Change 8

2-65