TM 9--2350--292--10

0100 00--3

WINCH ELECTRICAL SYSTEM TROUBLESHOOTING -- CONTINUED

0100 00

WINCH DRUM MALFUNCTION INDICATOR COMES ON

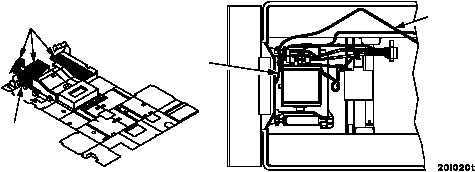

Step 1. Remove floor plates. Check for hydraulic leaks at level winder. Check that quick--disconnect on hose

33 and 34 (hydraulics for level winder) is properly connected.

Connect quick--disconnect, tighten connections, or notify unit maintenance if there are any damaged

hoses.

HOSE 33

HOSE 34

FLOOR

PLATE

FLOOR

PLATES

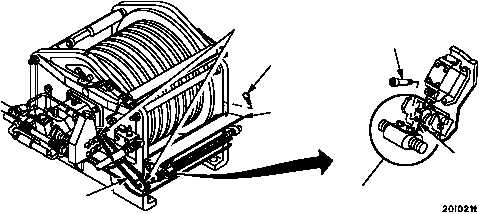

Check for cable problems including birdnesting, skipped wraps, kinks, broken strands, excess mud/debris

buildup, misalignment between cable on drum and trumpet. Check for damage to level wind drive chain

and sprockets. Remove two thumbscrews and raise diamond screw cover. Check for damage to level

wind components, check damaged/missing shoulder bolt or plate at the diamond screw to level wind inter-

face.

If there is damage to winch, level winder, cable, drive chain, or sprockets, or if shoulder bolt or plate is

missing or damaged, do not operate winch. Notify unit maintenance.

DIAMOND SCREW

COVER

SHOULDER

BOLT

PLATE

LEVEL WIND

DRIVE CHAIN

DIAMOND SCREW/LEVEL WIND

INTERFACE

LEVEL WIND

DRIVE SPROCKETS

THUMB

SCREW

Step 2. Use WINCH OVERRIDE switch and main winch operating lever to intermittently pay out and inhaul

winch cable to make sure main winch cable is wrapping and unwrapping properly during inhaul and

payout. Maintaining cable tension, use WINCH OVERRIDE switch and carefully payout main winch

cable just past the point where spooling malfunction occurred. Correct spooling malfunction.

Step 3. If problem still exists, notify unit maintenance.