TM 9--2350--292--20--1

AUXILIARY WINCH FAILS TO OPERATE OR DEVELOP FULL POWER --

CONTINUED

0096 00

CONTINUED FROM STEP U

yes

no

Tighten leaking connections and

remove restrictions. If restrictions

cannot be removed or if hose is

damaged, replace (WP 0568 00).

Verify fault is corrected.

Verify fault is

corrected.

W

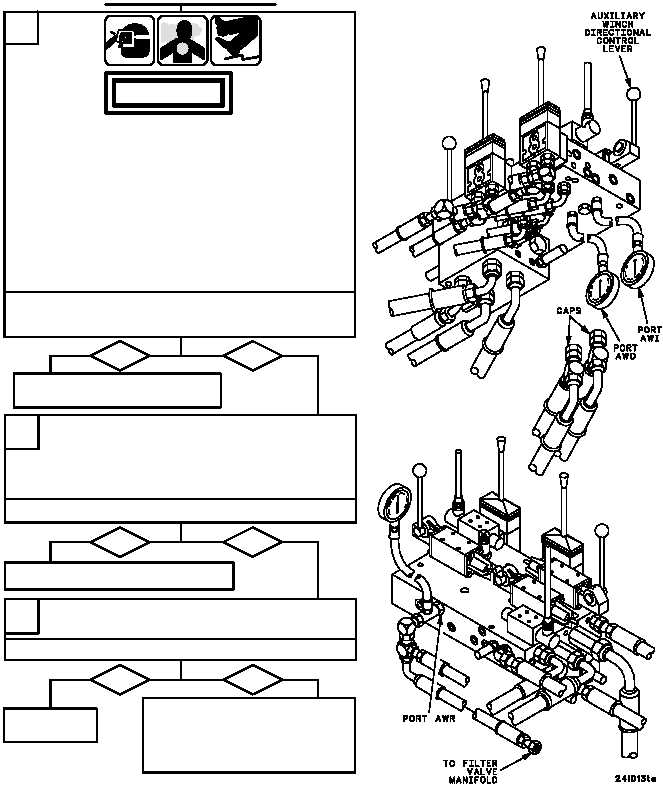

1. Disconnect hoses from ports AWI and AWO on the

hydraulic control valve manifold assembly. Cap hoses.

2. Install 0--4000 psi testing gauge assembly on ports AWI

and AWO.

3. Start main engine, energize hydraulics and set engine

speed to 1800 rpm (TM 9--2350--292--10).

4. Place auxiliary winch directional control valve lever in the

payout position and record gauge readings.

5. Place auxiliary winch directional control valve lever in

the inhaul position and record gauge readings.

6. Shut down hydraulics and main engine

(TM 9--2359--292--10).

no

yes

Replace auxiliary winch (WP

0086 00). Verify fault is corrected.

X

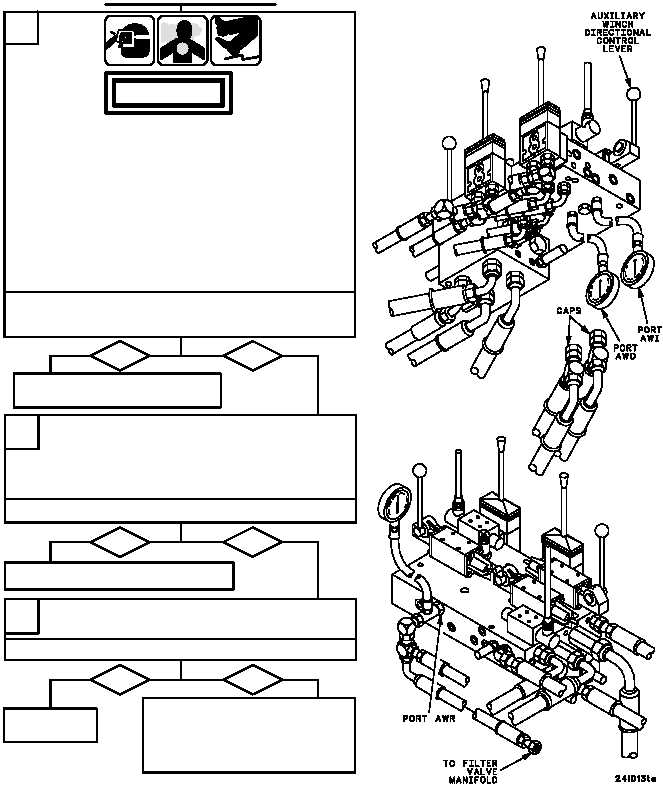

Is pressure at AWR port 140 psi or less?

1. Start Enhanced Diagnostics System Program

(WP 0086 00) and select the corresponding

symptom.

2. Perform step W steps 3 thru 6 and record

pressures at port AWR.

no

yes

Notify Direct Support Maintenance.

Y

Is hose free of leaks, restrictions, and damage?

Inspect hose from AWR port to filter valve manifold

for leaks, restrictions, and damage.

Is AWI pressure reading 140 psi or less in payout posi-

tion and AWO pressure reading is 140 psi or less in in-

haul position?

WARNING

END OF TASK

0096 00--11/12 blank