TM 9--2350--292--20--1

0187 00--165

PREVENTIVE MAINTENANCE CHECKS AND SERVICES INCLUDING

LUBRICATION INSTRUCTIONS -- CONTINUED

0187 00

TABLE 4 PREVENTIVE MAINTENANCE CHECKS AND SERVICES

INCLUDING LUBRICATION INSTRUCTIONS, ANNUALLY

INITIAL SETUP:

Tools and Special Tools

General mechanic’s tool kit (item 1, WP 0717 00)

Materials/Parts

Wiping rags (item 7, WP 0716 00)

For oil sampling:

Oil sampling bottle (8125--01--082--09697)

Oil sampling pump (4930--01--119--4030)

Plastic bag (item 48, WP 0716 00)

Shipping sack (8105--00--290--0340)

Personnel Required

Three

References

WP 0716 00

WP 0717 00

WP 0454 00

TM 9--2350--292--34

NOTE

Refer to PMCS temperature chart for proper lubricants to use at different temperature ranges.

ITEM

NO.

INTERVAL

LOCATION

ITEM TO

CHECK/

SERVICE

PROCEDURE

NOT FULLY

MISSION

CAPABLE

IF:

ANNUALLY

INTERIOR

1

Hydraulic

Reservoir AOAP

Sampling

WARNING

a. Park vehicle on a level surface

(TM 9--2350--292--10).

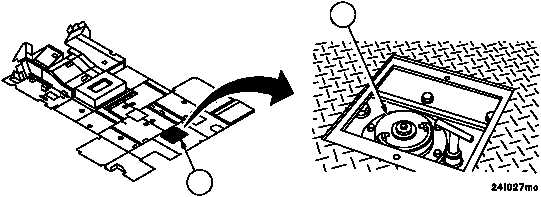

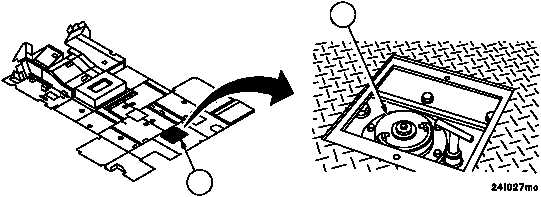

b. Open subfloor plate #28 (1)

(WP 0454 00).

c. Remove hydraulic reservoir fill cap (2)

(TM 9--2350--292--10).

d. Insert tube, suction enough hydraulic

fluid to fill sampling bottle.

e. Install hydraulic reservoir fill cap (2)

(TM 9--2350--292--10).

f. Close subfloor plate #28 (1)

(WP 0454 00).

Any metal

flakes or

other

contaminants

are seen.

Oil does not

pass

laboratory

testing.

1

2