TM 5-4240-501-14&P

GOV. CONTROLS & CARB. LINKAGE

General

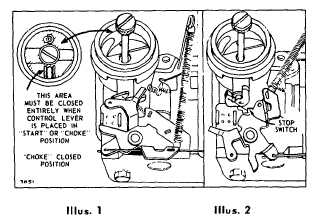

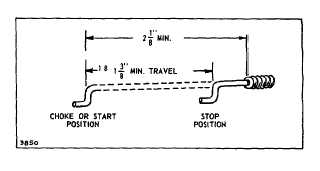

Fig. 4 illustrates typical remote control installations used

with Choke-A-Matic carburetors. To adjust, move remote

control lever to "FAST" position. Choke actuating lever

"A" should just contact choke shaft "B" or link "B" as

shown in Fig. 4. If not, loosen screw "C" slightly and

move casing and wire "D" in or out to obtain this

condition.

Fig. 4 - Choke-A-Matic Control (Typical)

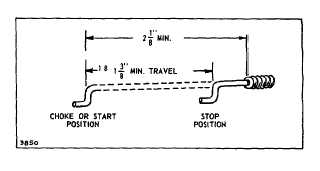

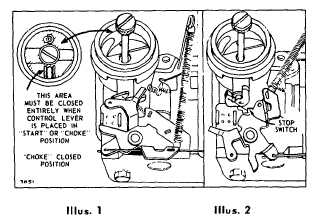

Check operation by moving remote control lever to

"START" or "CHOKE" position. Choke valve should be

completely closed. Fig. 5. Illus. 1. Then move remote

control lever to "STOP" position. Control must contact

stop switch blade. Fig. 5. Illus. 2.

Fig. 5 - Choke and Stop Position

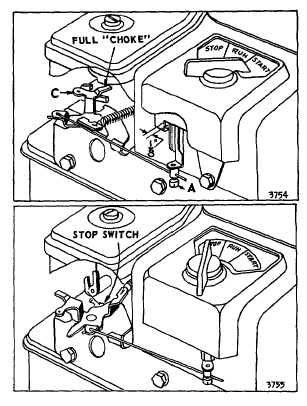

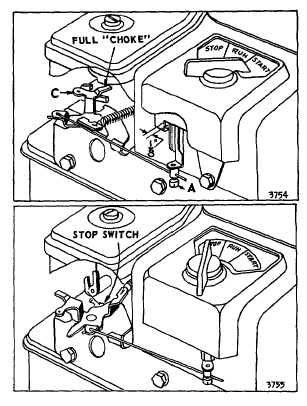

Travel of remote control wire must be a minimum of 1-

3/8" in order to achieve full "CHOKE" and "STOP"

position. Fig. 6.

Fig. 6 - Control Wire Travel

CHOKE-A-MATIC DIAL CONTROL

ADJUSTMENTS

Dial Controls seldom require adjustment unless blower

housing has been removed. To Adjust: Place dial control

knob in "Start" position. Loosen control wire screw "A" -

move lever "C" to full choke position. Allow a 1/8" gap

between lever and bracket as shown.

Fig. 7 - Choke-A-Matic Dial Control Adjustments

2