TM 5-4240-501-14&P

CARBURETION

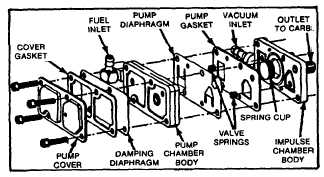

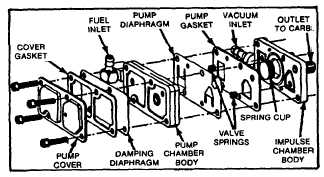

Fuel Pumps

Operation

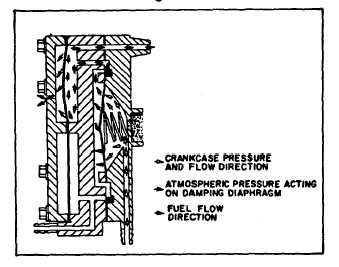

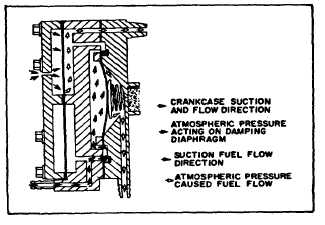

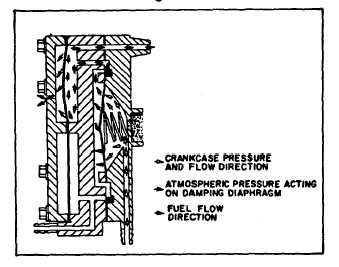

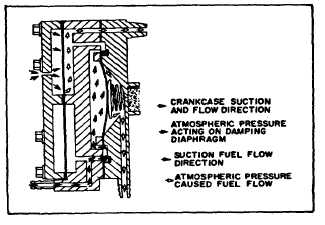

Operation of the fuel pump is illustrated in Figs. 119, 120

and 121. Any restriction in the fuel or vacuum lines will

affect operation. Also any leaks that cause air to get into

the fuel line or reduce vacuum in the vacuum line will

reduce performance.

Fig. 119

Fig. 120 - Fuel Flow with Crankcase Pressure

Fig. 121 - Fuel Flow Crankcase vacuum

To service fuel pump, pump should be removed from

carburetor or mounting bracket. When removing fuel

supply line from tank to pump, be sure to plug fuel line or

turn off fuel valve, if so equipped.

Disassemble fuel pump by removing four (4) 1/4" head

cap screws from pump cover. Separate pump cover,

pumping chamber and impulse chamber. Discard old

gaskets, diaphragms and springs. Clean pump parts in

carburetor solvent or lacquer thinner.

A repair kit is available. See Illustrated Parts Lists. The

kit includes all parts needed. Install chamber gasket

using locator pins. Place springs in spring recesses and

install pump diaphragm locator pins. Place pump

chamber body on impulse body using locator pins. Place

damping diaphragm and cover gasket on pump body.

Install cover and four (4) screws. Torque screws to 10-

15 in. lbs. (.12-.17 mkp, 1.13-1..69 Nm). See Fig. 119

for exploded view.

FUEL PUMPS,

ECCENTRIC OPERATED

To Replace Pump Diaphragm

Remove pump from cylinder and then remove four

screws to separate pump head from pump body.

With a narrow punch, drive lever pin out until pump lever

is loose. Pin may then be driven in either direction, but

need not be removed entirely. Remove old diaphragm,

but leave diaphragm spring in pump body.

Place new diaphragm into pump body with the slot in

shaft at right angles to the pump lever. Diaphragm spring

should fit into the cup under the diaphragm. Without the

lever spring, insert the pump lever into body holding the

diaphragm down. Fit the hook at the end of lever into the

slot in diaphragm shaft. Fig: 122.

Assemble Fuel Pump

Align holes in lever and body, then drive lever pin into

place. Place lever spring into body with inner end of

spring over the projection in pump body, then use a

screw driver to force outer end of spring into body until it

slips over the projection on lever. Fig. 122, Illus. 2.

Place pump head on body and partially insert the four

screws. Press pump lever down as far as possible and

then tighten the four screws.

34