TM 5-4240-501-14&P

CARBURETION

L. P. Fuel

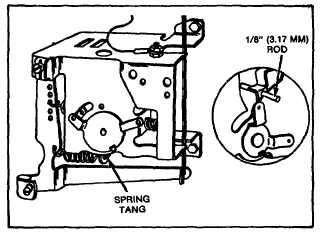

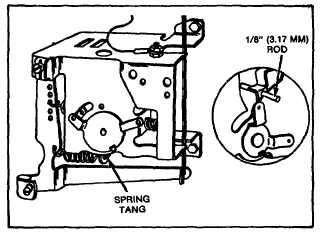

Governed Idle

Turn idle speed adjusting screw to obtain 1600 R.P.M.

while holding throttle lever against screw. Release

throttle lever. Align holes in control bracket and inside

lever with 1/8" diameter rod. Governor speed control

lever of equipment should be in IDLE position. Adjust if

necessary. Bend spring tang to obtain 1750 R.P.M.

Remove 1/8" diameter rod, Fig. 109.

Fig. 109 - Governed Idle Adjustment

Needle Valve Mixture (High Speed)

Move governor speed control lever to "FAST" position.

Turn needle valve in until engine slows or misses (lean

mixture), then turn it out past the smooth operating point

until engine runs unevenly (rich mixture). Now turn

needle valve to the midpoint between rich and leans so

the engine runs smoothly, Fig. 108.

Engine should accelerate smoothly. If engine does not

accelerate properly, the carburetor should be re-adjusted

usually to a slightly richer mixture.

L. P. GAS FUEL SYSTEM

The following information is provided to assist you in

servicing LP gas fuel systems. This information applies

only to Garretson Equipment Company systems installed

by Briggs & Stratton. For parts information refer to MS-

3915. Parts for the Garretson system must be obtained

from

a

Garretson

parts

distributor.

For

information about LP conversion kits, contact:

Garretson Equipment Co., Inc.

Box 111

Mount Pleasant, Iowa 52641

or

Beam Products Manufacturing Co.

3040 Rosslyn Street

Los Angeles, California 90065

For LP fuel systems not covered in this section contact

the manufacturer of the fuel system.

WARNING: LP gas fuel system should only be worked

on in a very well ventilated area. Many state, county and

city governments require that service be performed only

outdoors. Before loosening any fuel line connections,

have a fan blowing directly across the engine.

Checking and Adjusting Fuel System

Loosen fuel line at primary regulator. Openvalve on

cylinder for an instant, to be sure there is pressure in fuel

cylinder. Escaping gas can be heard. Shut off valve at

cylinder, Fig. 110, page 32.

Remove fuel line between primary and secondary

regulator (fuel controller). Attach pressure gauge to

outlet of primary regulator, leaving gauge connection

loose enough to permit a slight leakage of gas. (This will

permit adjustment of regulator under conditions of actual

gas flow.) Remove cap or top of primary regulator, Fig.

110.

Open fuel cylinder valve. Turn pressure regulating screw

in primary regulator, until a pressure of 1-1/2 pounds is

obtained at pressure gauge. Shut off fuel cylinder valve.

Re-assemble cap. Remove pressure gauge. Loosen

secondary regulator bracket from carburetor. Pull

secondary regulator away from carburetor so that short

rubber fuel line is disconnected. Assemble fuel line

between primary regulator and secondary regulator (fuel

controller). Secondary regulator must remain mounted so

the diaphragm is in a vertical plane, Fig. 110.

Open fuel cylinder valve. Apply soap suds to outlet at

the center of secondary regulator to which rubber fuel

line has been attached. If a bubble forms, it indicates

that the valve is leaking or not locking off. If no bubble

appears, press the primer button. A bubble should

appear,

30