TM 5-4240-501-14&P

CARBURETION

Cross-Over Flo-Jet

Inspection

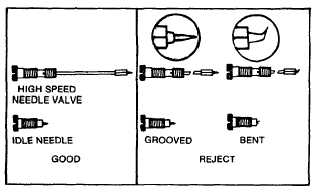

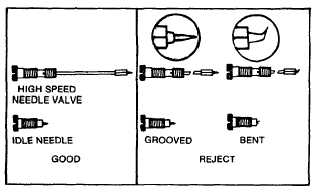

Check idle and high speed needle valves for burrs,

grooves or bent needle tips. Reject if damaged, Fig.

101. Check float for fuel in float, damage or leaks. If it

contains fuel or is crushed it must be replaced. If

carburetor leaks with new inlet needle valve, replace inlet

needle seat. See next paragraph.

Fig. 101

Replacing Pressed-In Float Valve Seat

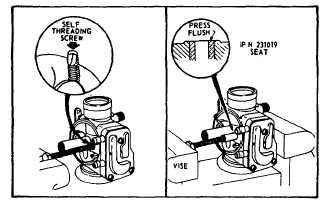

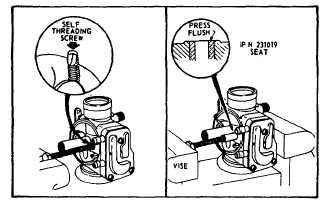

Use a #93029 self-threading screw or remove one self-

threading screw from a #19069 flywheel puller and clamp

head of screw in a vise. Turn carburetor body to thread

screw into seat. Fig. 102. Continue turning carburetor

body drawing seat out. Leave seat fastened to screw.

Insert new seat #231019 into carburetor body. (Seat has

starting lead.)

Fig. 102 - Replacing Float Valve Seat

Press new seat flush with body using screw and old seat

as a driver. See Fig. 102. Use care to insure seat is not

pressed below body surface or improper float to float

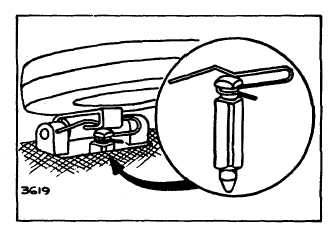

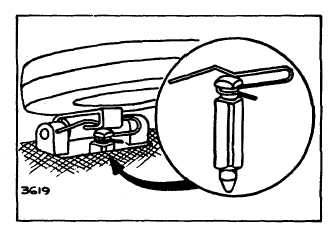

needle valve contact will occur. Install float valve as

shown in Fig. 103.

Fig. 103 - Float Needle Valve

Checking Float Level

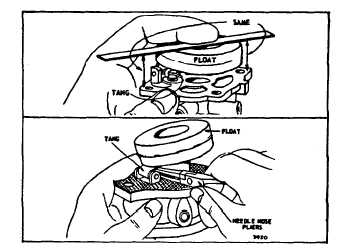

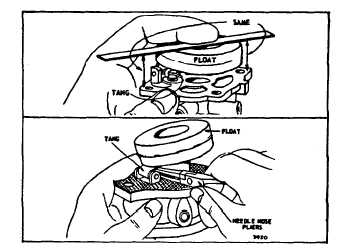

With float needle valve, float and float hinge pin installed,

hold carburetor upside down. The float should be

parallel to the bowl mounting surface. If not, bend tang

on float until they are parallel. DO NOT PRESS ON

FLOAT TO ADJUST, Fig. 104.

Fig. 104 - Checking Float Level

Repair Carburetor

Use new parts where necessary. Always use new

gaskets. Old gaskets take a set or harden and may leak.

Carburetor repair kits are available, see illustrated parts

list for part numbers. These carburetors use a viton tip

float needle and a pressed-in needle seat. The seat

does not need replacement unless the seat is damaged

or leaks with a new float needle.

28