TM 5-4240-501-14&P

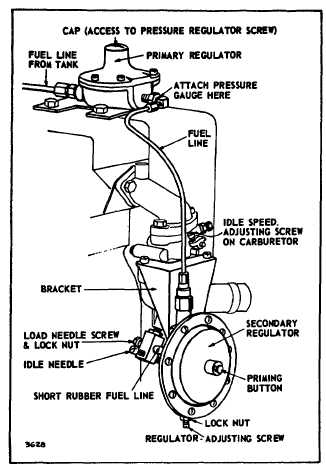

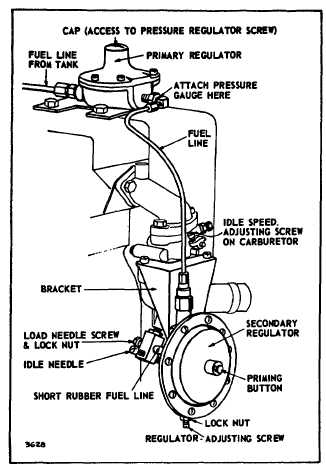

indicating fuel is flowing into regulator. Put soap suds on

the outlet again. Then slowly turn adjusting screw at

bottom of secondary regulator counterclockwise until a

bubble forms at the outlet. Then turn adjusting screw in

(clockwise) slowly until soap bubbles on outlet no longer

form. Hold adjusting screw at this point and tighten

locknut. Press primer button to allow fuel to flow.

Release and again put soap suds on outlet to make

certain the fuel shuts off. Repeat several times. If

bubble should form after primer button is released, the

adjusting screw should be turned in until flow stops and

soap bubble does not break or enlarge. Loosen fuel line

between regulators. Reassemble secondary regulator to

carburetor with short rubber fuel line in place. Tighten

fuel line, Fig. 110.

Adjusting Carburetor, L.P. Fuel System

See Fig. 110.

Loosen locknut on load needle screw and turn needle

screw in until it seats. Do not force; open 2-1/2 turns.

Turn idle needle in until it seats, then open one turn. If

engine will not be required to idle, leave idle needle

closed. Depress the primer button momentarily, then

start engine, run engine to allow it to warm up before

final adjustment. With engine running at normal

operating speed, turn the load needle screw in slowly

(clockwise) until engine starts to miss (lean mixture).

Then turn load screw out slowly past the point of best

operation until engine begins to run unevenly (rich

mixture). Then turn load screw in just enough so engine

will run smoothly. Hold load screw and tighten locknut.

Hold throttle at idle position, then release throttle.

Engine should accelerate quickly and smoothly.

If engine will be required to run at idle, turn the idle

speed adjusting screw on throttle until engine runs at

proper idle speed for engine model. See Check Chart.

Hold throttle at this point and turn the idle slowly in or out

until engine runs at maximum idle speed. Then re-adjust

idle speed screw until proper idle speed is obtained.

Allow throttle to open. Engine should accelerate quickly

and smoothly. If not, re-adjust load screw, usually to a

richer mixture. To stop engine, turn off fuel supply valve

at fuel cylinder.

CARBURETION

L.P. Fuel and Kerosene

Fig. 110 - Adjusting Carburetor, L.P. Fuel System

Starting Engine

To start engine, do not use choke, but depress primer

button momentarily, then start engine immediately. In

cold weather, it may be necessary to partially close the

carburetor choke valve to permit the engine to run

smoothly until the engine warms up.

Cleaning L.P. Gas Filter (Optional)

Unscrew filter head from filter body. Remove element

assembly from the head. Fig. 111. Wash the element in

commercial solvent cleaner or

gasoline.

If

the

accumulated dirt is gummy, we suggest a short soaking

period in solvent cleaner. The element should then be

rinsed in clean gasoline and blown with compressed air.

ALWAYS USE REVERSE FLOW FROM THE INSIDE

OUT. NEVER USE COMPRESSED AIR ON THE

OUTSIDE SURFACE OF THE ELEMENT. NEVER DIP

ELEMENT

IN

"BRIGHT

DIP"

OR

OTHER

ACID

SOLUTION.

31