STARTERS

Rewind Starters

Old Style with Guide Lug

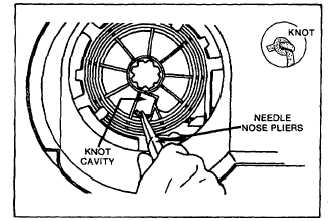

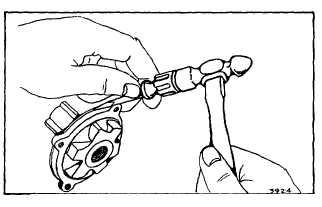

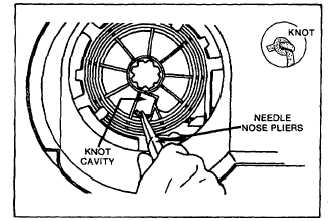

Tie a knot in rope and pull tight. Fig. 13. Make sure

knot in pulley does not contact bumper tangs. Fig. 11.

Current Style without Guide Lug

Tie a knot in rope and pull tight. Manipulate knot so it

can be pulled down into knot cavity. Fig. 13.

Fig. 13 - Tie Knot

Replace Rewind Assembly

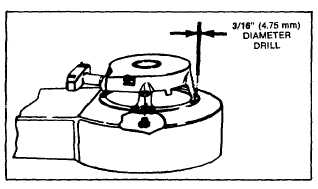

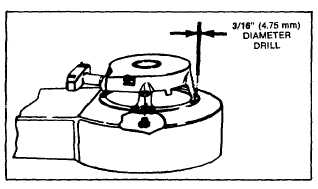

If original starter housing is spot welded to blower

housing, drill out spot welds using a 3/16"

diameter drill. Drill deep enough to loosen spot welds

ONLY. Locate replacement rewind assembly in desired

position. Install screws from inside blower housing up

through starter housing mounting leg. Fasten securely

with nuts as shown in Fig. 14.

Fig. 14

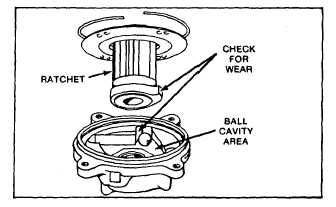

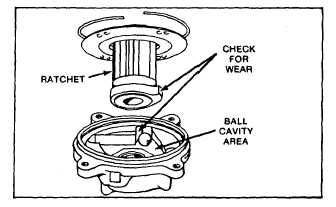

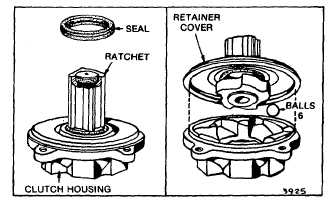

Starter Clutch (Old Style)

Inspect and clean starter clutch assembly as necessary.

Fig. 15 and 16. Do not oil ball cavity area.

Fig. 15 - Starter Clutch (Old Style)

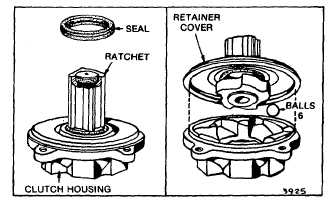

Starter Clutch (Sealed)

Fig. 16 - Sealed Clutch Assembly (Current Style)

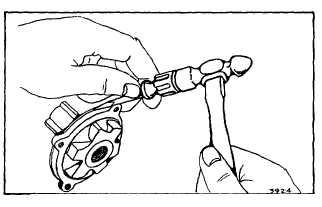

If necessary, the sealed clutch can be disassembled by

using a screwdriver or wedge to pry the retainer cover

from the housing, as shown in Fig. 17. Place one drop

of engine oil on end of crankshaft before replacing clutch

assembly on crankshaft. Tighten clutch to torque noted

on specification sheet for your model engine. DO NOT

run engine without screen screws assembled to clutch.

NOTE: Clean ratchet by wiping with cloth only.

Fig. 17 - Disassembling Sealed Clutch

3