STARTERS

Rewind Starters

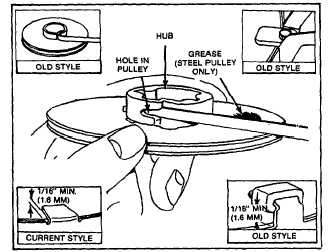

Fig. 6 - Install Spring

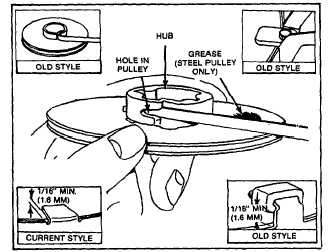

Place a dab of grease on pulley. Set pulley into housing

and bend tang down. See Fig. 6. Adjust tang gap as

shown. Pulley must be depressed fully into rewind

housing when measuring tang gap.

NOTE: Do not remove nylon bumper from old style tang

when replacing metal pulley with nylon pulley. Replace

nylon bumpers if worn.

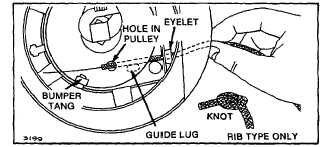

Wind Spring

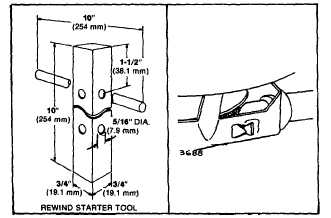

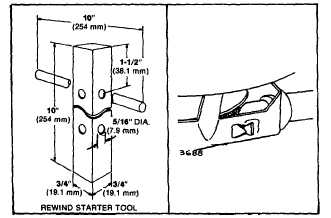

Place a 3/4" square piece of stock into center of pulley

hub or make rewind toot similar to one shown in Fig. 7.

GRASPING STOCK WITH A WRENCH, WIND PULLEY

COUNTERCLOCK-WISE UNTIL SPRING IS WOUND

TIGHT. Then back off pulley one turn or until hole in

pulley for rope knot and eyelet in blower housing are in

alignment. See Fig. 11 or 12.

Spring should be securely locked in smaller portion of

tapered hole. See Fig. 8.

Fig. 7

Fig. 8

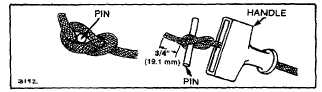

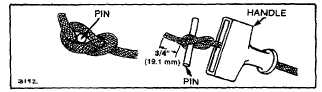

Install Rope

Inspect rope. Replace if frayed. Insert rope through

handle and tie a figure eight knot. Insert pin through knot

and pull tightly into handle. Fig. 9. ALWAYS SEAL

BOTH ENDS OF KNOT.

Fig. 9 - Install Rope

If re-using old rope, burn pulley end of rope with a match.

Wipe with waste cloth, using caution, while it is still hot,

to prevent swelling and unraveling.

NOTE: WHEN INSTALLING A NEW ROPE, CHECK

PARTS LIST TO BE SURE CORRECT DIAMETER AND

LENGTH ROPE IS USED.

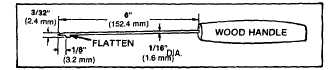

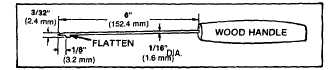

A rope inserter tool may be made by using a piece of

music wire or spring wire, and forming it as shown in Fig.

10.

Fig. 10 - Rope inserter

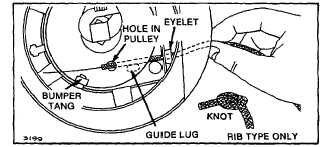

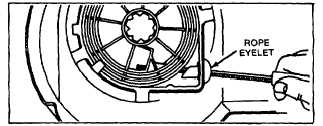

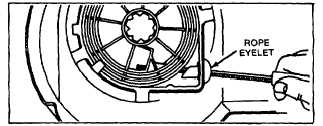

Thread wire and rope through rope eyelet in

housing and out pulley hole. (CAUTION: Rope

must pass inside a guide lug on metal pulley.) Fig. 11.

Fig. 11 - Inserting Rope, Old Style

Fig. 12 - Inserting Rope

2