COMPRESSION

Valve Seat Inserts

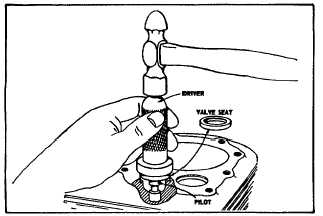

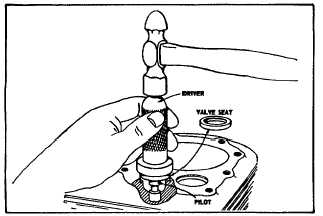

To Drive In New Valve Seat Insert

Select the proper valve seat insert and the correct pilot

and driver according to Table 3 & 4. You will note that

one side of the seat insert is chamfered at the outer

edge. This side should go down into the cylinder.

Insert the pilot into the valve guide. Then drive the valve

insert into place with the driver, as shown in Fig. 17.

The seat should then be ground lightly and the valves

and seats lapped lightly with grinding compound. Clean

thoroughly.

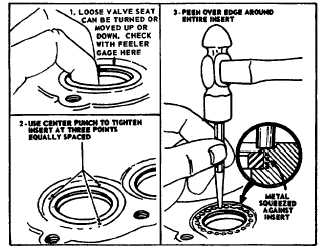

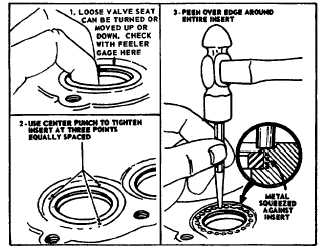

NOTE: Aluminum alloy cylinder models. Use the old

insert as a spacer between the driver and the new insert.

Drive new insert until it bottoms. Top of insert will be

slightly below cylinder head gasket surface. Then peen

around the insert as shown in Fig. 18.

Fig. 17 - Driving in Valve Seat

Fig. 18 - Peening Valve Seat

NOTE: Replace Cylinder if a .005" (0.13 mm) Feeler

Gauge enters between Valve Seat and

Cylinder.

To Counterbore Cylinder for Intake Valve Seat Cast

Iron Cylinder Models

These models must be counterbored to allow installation

of the intake valve seat insert. Select proper seat insert,

cutter shank, counterbore cutter, pilot and driver

according to Table 4.

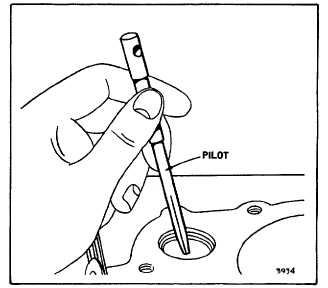

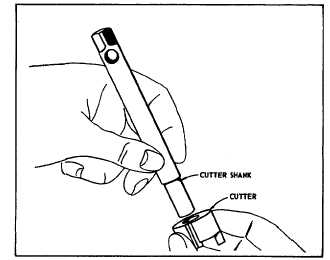

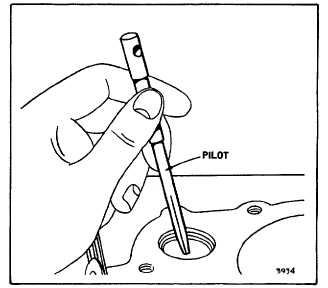

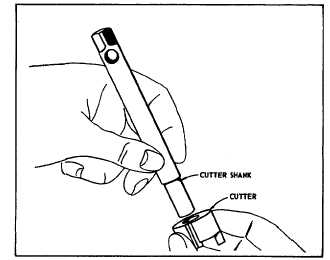

Insert pilot in intake valve guide. See Fig. 19. Assemble

correct counterbore cutter to cutter shank as shown in

Fig. 20.

Counterbore the cylinder by hand until stop on cutter

touches the top of the cylinder. Fig. 21. Do not force

the cutter to one side or it will cut oversize. Blow out all

chips. Use knock out pin 19135, to remove cutter from

cutter shank.

Fig. 19 - Inserting Pilot

Fig. 20 - Inserting Cutter Shank

8