COMPRESSION

Valves & Guides

TABLE NO. 2

VALVE TAPPET CLEARANCE

MODEL SERIES

INTAKE

EXHAUST

ALUMINUM

MAX.

MIN.

MAX.

MIN.

CYLINDER

Milli-

Milli-

Milli-

Milli-

Inches

meter

Inches

meter

Inches

meter

Inches

meter

6B, 60000, 8B, 80000,

82000, 92000, 94000,

100000, 110000, 130000,

.007

0.18

.005

0.13

.011

0.28

.009

0.23

140000, 170000, 190000,

220000, 250000

Milli-

Milli-

Milli-

Milli-

CAST IRON CYLINDER

Inches

meter

Inches

meter

Inches

meter

Inches

meter

5, 6, 8, N, 9, 14, 19,

.009

0.23

.007

0.18

.016

0.41

.014

0.36

190000, 200000

23, 230000, 240000,

.009

0.23

.007

0.18

.019

0.48

.017

0.43

300000, 320000

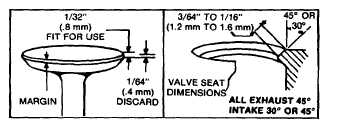

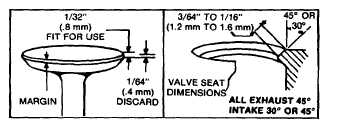

To Reface Valves and Seats

Faces on valves and valve seats should be resurfaced

with a valve grinder or cutter, to an angle of 45°. NOTE:

SOME ENGINE MODELS HAVE A 300 INTAKE VALVE

AND SEAT. Valve and seat should then be lapped with

a fine lapping compound to remove grinding marks and

assure a good seat. Valve seat width should be 3/64" to

1/16" (1.19-1.58 mm). Fig. 7. If the seat is wider, a

narrowing stone or cutter should be used. If either the

seat or valve is badly burned, it should be replaced.

Replace valve if margin is 1/64" (0.4 mm) or less after

refacing. Fig. 7.

Fig. 7 -- Valve and Seat Dimensions

To Check and Adjust Tappet Clearance

Insert the valves in their respective positions in the

cylinder. Turn the crankshaft to top dead center, end of

compression stroke. Both valves are now closed. Then

check clearance on the intake and exhaust valves with

feeler gauge. See Table 2. Grind off the end of the

valve stem if necessary, to obtain proper clearance.

CAUTION: Piston MUST be at top dead center at the

end of compression stroke to assure both valves being

closed.

NOTE: Check clearance cold.

To Install Valves

Some engines use the same spring for intake and

exhaust side, while others use a heavier spring on the

exhaust side. Compare springs before installing.

If retainers are held by a pin or collars, Fig. 2, Illus. 1 and

2, place valve spring and retainer (and cup on Model

Series 9, 14, 19, 20, 23, 24 and 32) into valve spring

compressor 19063. Compress the spring until it is solid.

insert the compressed spring and retainer (and cup when

used) into the valve chamber. Then drop the valve into

place, pushing the stem through the retainer. Hold the

spring up in the chamber, and the valve down. insert the

retainer pin with a needle nose pliers or place the collars

in the groove in the valve stem. Lower the spring until

the retainer fits around the pins or collars, then pull out

the spring compressor. Fig. 3. Be sure pin or collars

are in place.

If self-lock retainer, Fig. 2, Illus. 3, is used, compress

retainer and spring with compressor 19063. Large

diameter of retainer should be toward front of valve

chamber. Fig. 8. Insert compressed spring and retainer

into valve chamber. Drop the valve stem through larger

area of retainer slot and move the compressor so as to

center the small area of the valve retainer slot onto the

valve stem shoulder. Release the spring tension and

remove the compressor.

3