GOVERNORS

Repair & Adjustment

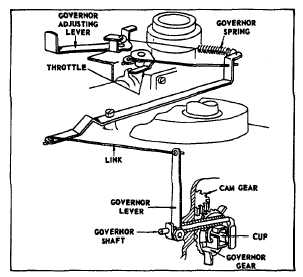

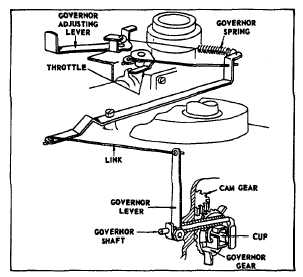

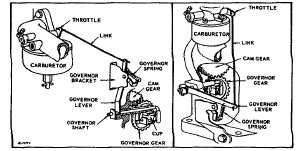

Fig. 15. Vertical Shaft

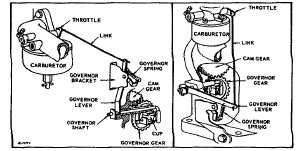

Fig. 16. Large Aluminum Engines

Re-Assembly

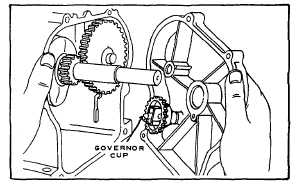

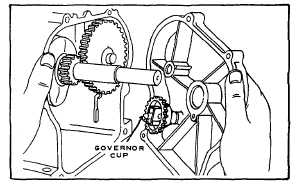

On horizontal crankshaft models, the governor rides on a

short stationary shaft and is retained by the governor

shaft, with which it comes in contact after the crankcase

cover is secured in place. Press governor cup against

crankcase cover to seat retaining ring on shaft, prior to

installing crankcase cover. It is suggested that the

assembly of the crankcase cover be made with the

crankshaft in a horizontal position. The governor shaft

should hang straight down parallel to the cylinder axis.

Fig. 17. If the governor shaft is clamped in an angular

position, pointing toward the crankcase cover, it is

possible for the end of the shaft to be jammed into the

inside of the governor assembly, resulting in broken

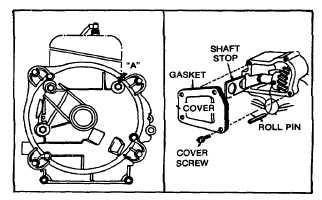

parts when the engine is started. After the crankcase

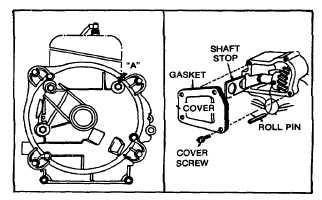

cover and gasket are in place, install cover screws. Be

sure that screw "A," Fig. 19, has nonhardening sealant

on threads of screw. Complete installation of remaining

governor linkages and carburetor and then adjust

governor shaft and lever.

Fig. 17. Showing Governor Shaft in Proper Position

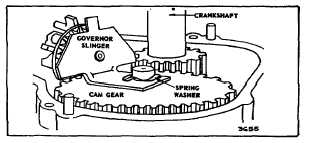

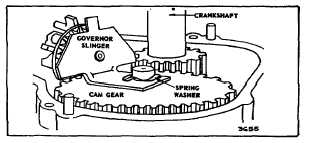

On vertical crankshaft models the governor is part of the

oil slinger and is installed as shown in Fig. 18. Models

100900 and 130900 use spring washer as shown in Fig.

18. Before installing sump be sure that governor cup is

in line with governor shaft paddle. Install sump cover

and gasket being sure screw "A," Fig. 19 has

nonhardening sealant on threads.

Fig. 18. Shows Spring on Camshaft after Governor is

Installed. Models 100900 and 130900 Only.

NOTE: On right angle auxiliary drive power take off

models, screw "A" does not need sealant but the four

screws holding the gear sump cover do need sealant.

See insert, Fig. 19.

Fig. 19. Sealant on Screw "A"

6